The pallet manufacturing industry is currently grappling with a series of challenges that significantly impact its efficiency and profitability. Manual labor dominates the production process, leading to low productivity, high labor costs, and a substantial amount of wasted materials due to a high rejection rate. These issues have become a bottleneck for many pallet factories, hindering their growth and competitiveness in the market.

Let's take a look at the story of a traditional pallet factory. Before the introduction of automated nailing machines, this factory faced the same problems as many others. With a workforce of 20 workers, they could only produce about 500 pallets in an 8 - hour shift. The quality of the pallets was inconsistent, and the rejection rate was as high as 10%, which meant a significant waste of materials and additional costs.

However, everything changed when they decided to upgrade their production line with an automated nailing machine. After the implementation, the factory's production capacity doubled. With only three operators, they could now produce 1000 pallets in the same 8 - hour shift. The quality of the pallets became more stable, and the rejection rate dropped to less than 1%. As a result, the factory's profit increased by 30% within a year.

Now, let's dive into the five core advantages of the automated nailing machine:

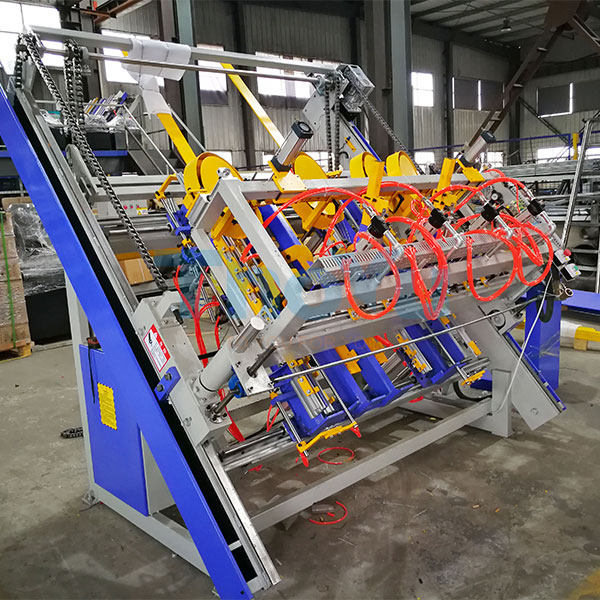

The dual - station design of the automated nailing machine allows for simultaneous operation. While one station is in the nailing process, the other can be loaded with new materials. This significantly reduces idle time and boosts the overall production efficiency. In a real - world scenario, a factory using a single - station machine might produce 300 pallets per 8 - hour shift, while a factory with a dual - station automated nailing machine can produce up to 600 pallets in the same time frame.

The machine is precisely manufactured according to European and American standards. This is a significant advantage for pallet factories aiming to export their products. With the increasing demand for high - quality pallets in the international market, compliance with these standards can enhance a factory's export competitiveness. A third - party testing report shows that the pallets produced by this machine fully meet the strict requirements of European and American markets, giving factories an edge over their competitors.

The automated nailing machine has an extremely low scrap rate. Thanks to its advanced control system, the machine can accurately position the nails, minimizing the chances of mis - nailing or over - nailing. This reduces material waste and saves costs. For example, a traditional manual nailing process might waste about 5% of the wood materials, while the automated nailing machine reduces this waste to less than 1%.

The machine comes with an automatic stacking and flipping function. After the nailing process, the pallets are automatically stacked and flipped, which reduces the need for manual labor. This not only improves the production flow but also reduces the risk of workplace injuries. In a traditional factory, it might take two workers to handle the stacking and flipping process, while the automated machine can complete this task without any additional human intervention.

The machine offers millimeter - level precision control. This ensures that each pallet is produced with the same high quality and consistency. A third - party expert evaluation indicates that the deviation of the nail positions is less than 1mm, which is crucial for the stability and durability of the pallets. This high - precision control also helps factories maintain a good reputation in the market.

To further enhance the credibility of these advantages, we have incorporated third - party testing reports and expert evaluations. These independent validations confirm the machine's performance and quality.

As you reflect on the current situation of your own factory, are you still struggling with low efficiency, high labor costs, and inconsistent quality? It's time to consider whether an upgrade to your production line is necessary. By investing in an automated nailing machine, you can make your pallet manufacturing process more intelligent and profitable. Click here to learn more about how this machine can transform your business!