The waste wood recycling industry has long been grappling with two significant challenges: resource waste and environmental pressure. A large amount of waste wood is discarded without proper utilization, not only wasting valuable resources but also causing environmental pollution. In the face of these challenges, how can waste wood recycling companies break through and enhance production efficiency? The answer lies in the dual - mode pressing wood pallet machine introduced by Zhengzhou Tuoyu Electromechanical.

The four - column hydraulic structure is the cornerstone of the machine's high - performance operation. This design ensures both precision and strength during the pallet production process. Unlike traditional structures, the four - column hydraulic system provides a more stable force distribution, which means that each pallet produced has consistent quality. The precision of this structure reduces the error rate in production, ensuring that the pallets meet the strictest industry standards.

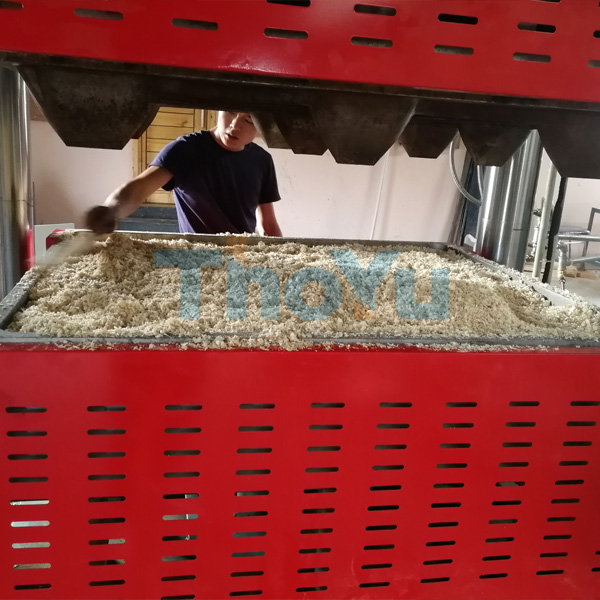

The automatic control system is another highlight of this machine. It significantly enhances the production capacity. With this system, the machine can complete a series of complex operations automatically, such as feeding, pressing, and discharging. This not only reduces the need for manual labor but also speeds up the production process. On average, the machine can produce a wooden pallet in just 30 seconds. Based on an 8 - hour working day, it can produce up to 240 pallets per day, a remarkable figure compared to traditional equipment.

Safety is always a top priority in industrial production. The dual - mode pressing wood pallet machine is equipped with thermal protection and overload protection systems. The thermal protection system monitors the temperature of the machine in real - time. If the temperature exceeds the safe range, the system will automatically shut down the machine to prevent damage caused by overheating. The overload protection system, on the other hand, detects excessive loads on the machine. When an overload is detected, it stops the operation immediately, protecting both the machine and the operators.

Traditional wood pallet production equipment often suffers from low efficiency and high costs. Manual operations are time - consuming and error - prone, and the production capacity is limited. In contrast, the dual - mode pressing wood pallet machine offers a revolutionary solution. The high - speed production rate of 30 seconds per pallet and 240 pallets per day means that companies can meet large - scale orders in a shorter time. Moreover, the automatic control system reduces labor costs, and the precision of the four - column hydraulic structure reduces material waste, thus optimizing the overall production cost.

The dual - mode pressing wood pallet machine has been well - received in the European market. European customers, known for their high - standards and strict requirements, have recognized the machine's performance. Their positive feedback serves as strong evidence of the machine's reliability and efficiency. Additionally, Zhengzhou Tuoyu Electromechanical has over 10 years of technical experience in this field. This long - standing experience has allowed the company to continuously improve the machine, ensuring that it meets the ever - changing market demands.

For waste wood recycling companies, the dual - mode pressing wood pallet machine offers both sustainable development and economic benefits. From a sustainable development perspective, it enables the effective reuse of waste wood, turning waste into valuable resources. This not only reduces environmental pollution but also contributes to the conservation of natural resources. Economically, the machine helps companies reduce production costs and increase production efficiency, thereby increasing profits. It truly allows waste wood to become a source of profit.

If you are looking to enhance the efficiency of your waste wood recycling business, the dual - mode pressing wood pallet machine from Zhengzhou Tuoyu Electromechanical is the ideal choice. It will help you open a new chapter in green production and achieve both environmental and economic goals. Don't miss this opportunity to transform your business. Click here to learn more about the product and start your green production journey!