For pallet producers in Europe and beyond, the transition from manual to automated production isn’t just about speed—it’s about reducing training time, minimizing downtime, and empowering every operator to contribute immediately. At郑州拓宇机电设备有限公司 (Zhengzhou Toyu Machinery Equipment Co., Ltd.), their new touchscreen-controlled pallet leg nailing machine delivers exactly that: a smarter way to build high-quality European-style pallets with minimal friction.

Traditional nailing machines often require weeks of training for operators to master complex controls—especially when dealing with variable timber thicknesses or custom block configurations. This leads to low productivity during ramp-up, frequent errors, and higher labor costs. The Toyu solution tackles these issues head-on by simplifying the interface while boosting precision.

“We trained three new workers in just three days—and now they’re producing over 120 pallet legs per hour without supervision.”

—— Marko K., Operations Manager, Baltic Pallet Solutions (Poland)

With intuitive touchscreen navigation, even employees with zero experience in industrial machinery can operate the device effectively within 72 hours. Unlike legacy systems that rely on physical buttons, rotary dials, or confusing menu hierarchies, this machine uses visual prompts, real-time feedback, and preset profiles tailored to different pallet types (e.g., Euro-pallets, flat-block designs).

Data shows that companies using this system report an average reduction of 65% in initial setup time and a 40% decrease in operator-induced errors within the first month of deployment.

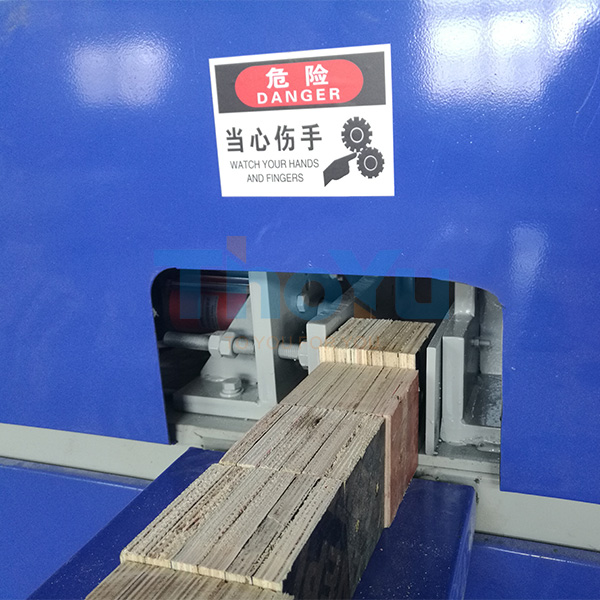

Beyond ease-of-use, the machine’s simplified mechanical structure reduces maintenance needs by up to 50%. Key components like Schneider Electric electrical systems and Airtac pneumatic parts ensure reliability, while modular design allows quick access to critical areas—no more disassembling entire units for minor adjustments.

This is not just automation—it’s intelligent automation. Operators don’t need engineering degrees to troubleshoot. They just tap the screen, follow guided diagnostics, and resume work faster than ever before.

One manufacturer in Germany reported saving €2,800/month in training expenses alone after switching to the Toyu system. With fewer stoppages, consistent output quality, and reduced waste from misaligned nails, the return on investment typically occurs within 4–6 months—not years.

If you're still relying on outdated equipment, it's time to ask: What are you losing while waiting for your team to catch up?

Get a free demo video + technical datasheet for the Touchscreen-Controlled Pallet Leg Nailing Machine — designed for fast adoption, easy operation, and lasting efficiency.

Watch Demo & Download Specs →