Did you know that over 72% of small to mid-sized tray manufacturers report inefficiencies in manual assembly processes? In today’s competitive market, speed and precision aren’t just advantages—they’re survival skills. That’s where the Tray Leg Nailing Machine comes in.

Designed specifically for European-style pallets and block tray production, this machine combines industrial-grade reliability with intuitive operation—so your team can go from zero to hero in just three days of training. No complex certifications. No steep learning curve. Just plug it in, train your staff, and start producing faster.

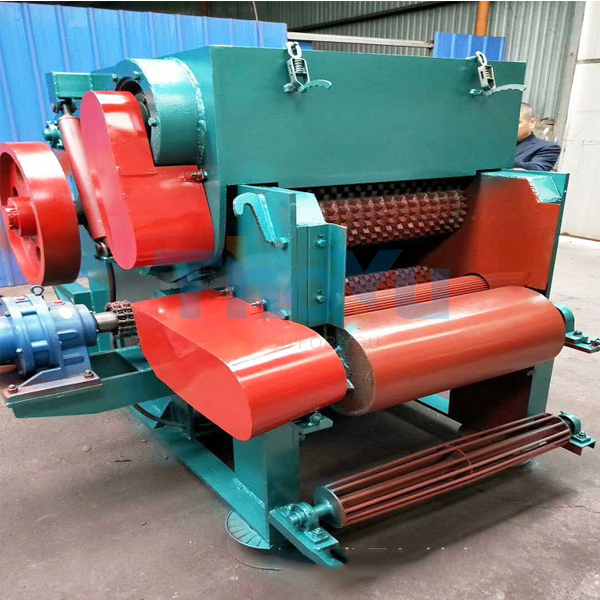

The secret lies in its core engineering:

One manufacturer in Poland reported a 35% increase in daily output after switching from hand-nailing to this automated solution. Their lead time dropped from 7 days to 4—and their customer satisfaction score rose from 3.8 to 4.6 out of 5.

We’ve heard the concerns: “Our workers don’t speak English.” “We have no technical background.” Here’s what we say: It doesn’t matter.

Our 3-day training program includes:

By Day 3, operators can confidently handle common issues like misaligned nails or inconsistent pressure—all without calling support. That means less downtime, fewer errors, and more trust from your team.

In fact, one factory in Turkey saw a 40% reduction in operator-related defects within two weeks of full adoption—proving that simplicity drives quality.

Stop losing hours to manual labor. Start building smarter, faster, and with confidence.

Get Your Free Demo & Training Plan Today