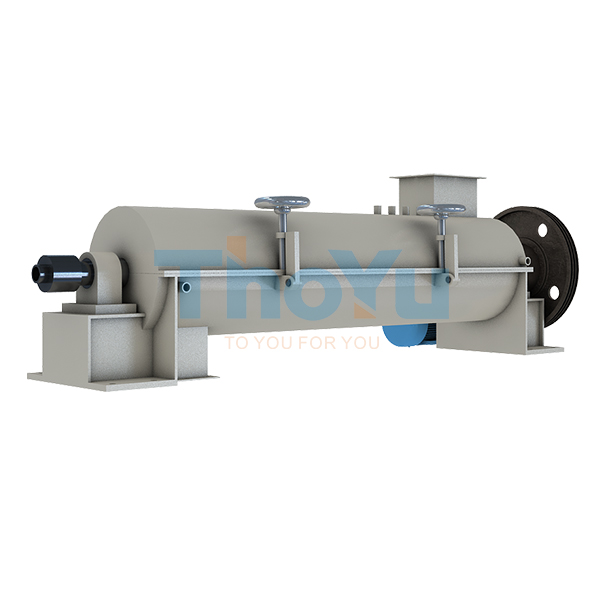

In the global wood pallet production industry, traditional glue mixing equipment has long been plagued by issues such as low efficiency, high waste of adhesives, and unstable product quality. As the demand for automation and digitization in manufacturing grows, there is an urgent need for innovative technologies to drive industry transformation. Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has stepped up to this challenge with its revolutionary ring-type glue mixer.

The ring-type glue mixer represents a significant technological leap in the wood pallet production process. By integrating the raw material mixing and gluing processes, it streamlines the production line and improves overall efficiency. For example, in a traditional wood pallet production line, the separate mixing and gluing steps often result in long production cycles and increased labor costs. With the ring-type glue mixer, these two processes are combined, reducing the production time by up to 30%.

The ring-type glue mixer's integrated process is a game-changer. It ensures that the raw materials are evenly mixed and the glue is applied uniformly, which is crucial for the quality of the final wood pallet product. This integrated approach not only improves the strength and durability of the pallets but also reduces the risk of delamination and other quality issues. According to industry data, pallets produced using the ring-type glue mixer have a 20% higher load-bearing capacity compared to those made with traditional equipment.

The advanced stirring structure of the ring-type glue mixer is designed to maximize the mixing efficiency. It uses a unique circular motion to ensure that all the raw materials and adhesives are thoroughly mixed. This results in a more consistent mixture, which in turn leads to better product quality. In addition, the stirring structure is easy to clean, reducing maintenance time and costs.

The forced cooling system is another key feature of the ring-type glue mixer. It helps to control the temperature during the mixing process, preventing the adhesive from overheating and losing its effectiveness. This system can reduce the temperature of the mixture by up to 15 degrees Celsius, significantly improving the quality and stability of the glue. As a result, the waste of adhesives is reduced by up to 25%, which is a substantial cost-saving for wood pallet production enterprises.

Traditional glue mixing equipment often suffers from problems such as uneven mixing, excessive adhesive waste, and quality instability. The ring-type glue mixer addresses these issues head-on. By providing a more efficient and precise mixing and gluing process, it eliminates the waste caused by over-application of adhesives and reduces the number of defective products. For instance, a wood pallet manufacturer in Europe reported a 40% reduction in adhesive waste and a 35% decrease in defective products after switching to the ring-type glue mixer.

There are numerous real-world examples that demonstrate the effectiveness of the ring-type glue mixer. In North America, a large wood pallet production company implemented the ring-type glue mixer in its production line. After six months of operation, the company saw a significant improvement in production efficiency, product quality, and cost savings. The company's production capacity increased by 25%, and the overall production cost was reduced by 18%.

The ring-type glue mixer has also gained international recognition. It has been exported to more than 20 countries and regions, including Europe, Asia, and North America. According to market research, the market share of the ring-type glue mixer in the global wood pallet production equipment market is expected to reach 15% within the next three years.

The ring-type glue mixer from Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. is a revolutionary product that is driving the wood pallet production industry towards automation and digital transformation. Its innovative features and proven effectiveness make it an ideal choice for wood pallet production enterprises looking to upgrade their technology and improve their competitiveness.

Are you ready to take your wood pallet production to the next level? Click here to learn more about the ring-type glue mixer and how it can benefit your business. We also invite you to share your experiences and thoughts on the future of wood pallet production in the comments below.