The wood pallet manufacturing industry faces persistent challenges in achieving uniform adhesive application while minimizing material waste. Recognizing these pain points, Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has pioneered the Ring Mixer — an advanced adhesive mixing machine engineered specifically to amplify production efficiency and reduce costly glue waste. This cutting-edge solution integrates raw material blending and adhesive application processes, driving transformative improvements in product quality and operational costs.

Traditional adhesive mixing methods in wood pallet plants often suffer from uneven blending, extended processing times, and elevated wastage rates— with glue loss contributing up to 15-20% of material inefficiency.[1] Moreover, inconsistent adhesive quality can cause compromised pallet strength and durability, risking customer dissatisfaction and increased rework costs.

In an era where cost control and sustainable manufacturing are paramount, manufacturers seek automated, precise, and smart equipment to lower operational expenses while ensuring consistent product performance.

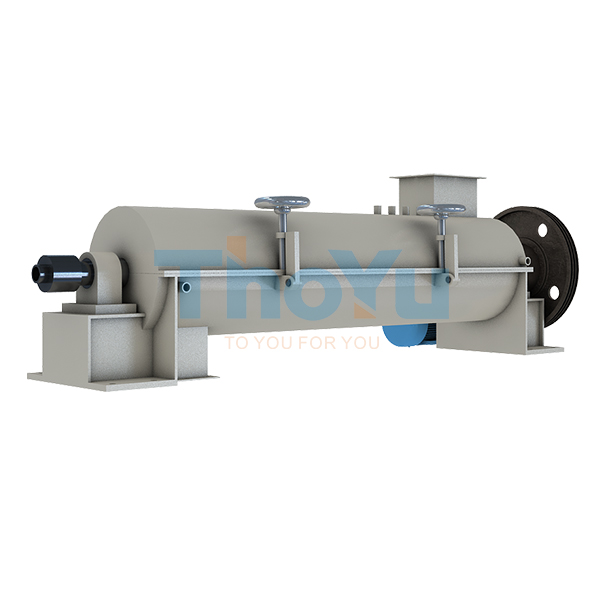

The Ring Mixer leads the market with its patented technology that merges raw material mixing and glue spreading within a single system. This integrated process enhances the homogeneity of adhesive blends, directly impacting the bonding quality of wood pallets.

These engineering breakthroughs lead to a 25% reduction in glue consumption and a 30% increase in mixing efficiency compared to conventional mixers. Additionally, consistency in adhesive viscosity and curing times has improved product yield and quality stability.

| Feature | Traditional Mixers | Ring Mixer |

|---|---|---|

| Adhesive Waste | 15-20% loss | Below 10%, saving up to 25% |

| Mixing Time | Average 12 minutes | Reduced to 8 minutes (30% faster) |

| Temperature Control | Manual or none | Automated forced cooling system |

| Automation & Connectivity | Low | Fully integrated, Industry 4.0 compatible |

Such comprehensive functionalities empower manufacturers to cut costs significantly, optimize resource usage, and maintain superior product standards – a vital advantage in a competitive global market.

A leading wood pallet manufacturer in Germany integrated the Ring Mixer into its production line in 2023. Within six months, documented results showed a:

Their plant manager noted, "The Ring Mixer's control precision and cooling capabilities have not only improved our product consistency but also accelerated our shift towards smart factory automation. It’s a game-changer for sustainable and efficient pallet manufacturing."

Additionally, over 50 countries across Europe, Asia, and the Americas have validated the Ring Mixer’s effectiveness through certification and direct operational feedback, bolstering its reputation as a trusted industry standard.

The customized automation and data connectivity features embedded in the Ring Mixer allow seamless integration with broader factory management systems. Real-time analytics facilitate predictive maintenance, material tracking, and quality assurance, enabling manufacturers to transition from manual, labor-intensive operations to digitally managed production lines.

This strategic upgrade not only supports environmental sustainability goals through waste reduction but also positions companies ahead in an increasingly digitized supply chain ecosystem.