In today’s competitive wood pallet manufacturing industry, efficiency isn’t just an advantage—it’s a survival necessity. Traditional methods often rely on manual labor for leg-to-board assembly, leading to inconsistent quality, frequent downtime, and rising labor costs. According to a 2023 industry report by Wood Packaging International, companies using outdated processes experience up to 25% more production delays and 18% higher defect rates compared to those adopting automation.

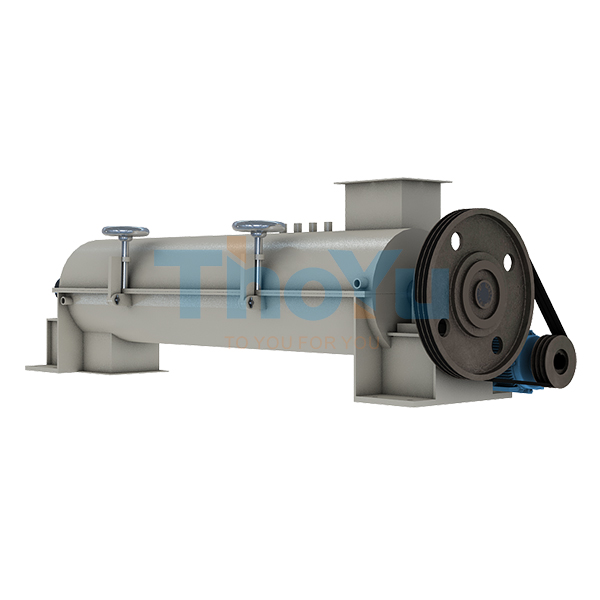

The Topu Machinery Auto Nail Gun Pallet Leg Machine addresses these pain points head-on. Designed with a robust PLC control system and user-friendly HMI interface, it delivers consistent nail placement accuracy within ±0.5mm—critical for load-bearing strength in logistics applications. Unlike older models that require constant recalibration, this machine maintains precision across 8+ hours of continuous operation, reducing stoppages by an average of 40% (based on pilot installations at three major European pallet producers).

Its modular design allows operators to switch between single- or dual-nail configurations in under 10 minutes—a feature that cuts employee training time from 3 days to just 1 day. This flexibility makes it ideal for manufacturers handling multiple pallet sizes, from standard EUR to custom industrial variants.

What truly sets this machine apart is its customization capability:

One client in Poland reported a 32% increase in daily output after integrating the machine into their existing line—without hiring additional staff. Another in Dubai noted a 20% reduction in material waste due to fewer misaligned joints.

For B2B buyers sourcing from China, the value isn’t just in speed—it’s in reliability. The Topu machine has been tested under harsh conditions in warehouses across Southeast Asia, North America, and the Middle East, proving resilient even in high-humidity environments where other machines fail.

With built-in diagnostics, remote monitoring via cloud-based dashboard, and easy maintenance access, downtime is minimized and productivity stays high—even when technicians aren't on-site.

Whether you're scaling up for e-commerce fulfillment centers or optimizing legacy lines for sustainability, this solution offers measurable ROI within 6–9 months through reduced labor costs, fewer rejects, and faster turnaround times.