In the fast-paced world of pallet manufacturing, downtime can be a critical bottleneck impacting both productivity and profitability. Traditional leg nailing processes often involve complex training cycles, frequent machine stoppages, and high labor costs. Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd has answered these challenges with their fully automatic Pallet Leg Nailing Machine, optimized specifically for European-style pallet production. Designed to turn your production line from waiting into seamless operation, this machine promises a quick learning curve and substantial efficiency boosts.

Manufacturers in the pallet industry frequently face several limiting issues:

These pain points collectively result in delayed delivery schedules, increased production costs, and reduced overall competitiveness.

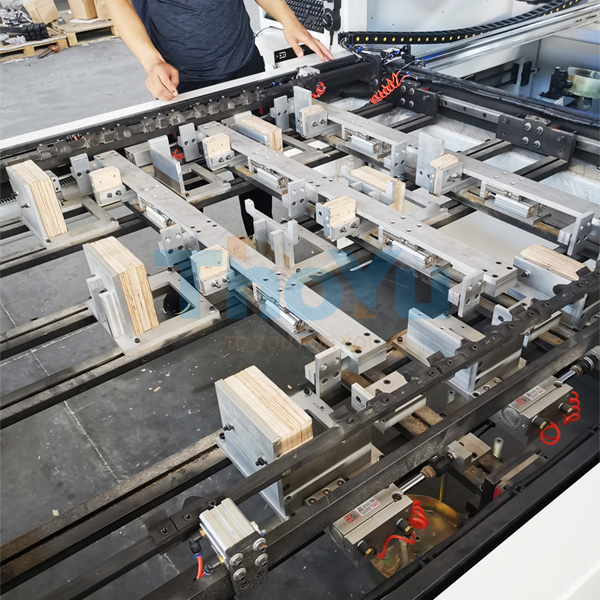

The Pallet Leg Nailing Machine combines cutting-edge automation with intuitive design, featuring an integrated PLC control system alongside a user-friendly touchscreen interface. This streamlined operation removes many traditional complexities:

By reducing human errors and simplifying control, the machine supports a stable and sustainable manufacturing process.

The three-day rapid onboarding period enables manufacturers to achieve "zero-delay commissioning," accelerating the ROI significantly. Key benefits include:

| Benefit | Estimated Impact |

|---|---|

| Downtime reduction after installation | Up to 40% |

| Operator training duration | Less than 3 days |

| Labor cost savings | 15%-25% annually |

| Maintenance downtime | Minimal, thanks to modular design |

Whether a small-medium enterprise or a larger-scale operation, the Pallet Leg Nailing Machine adapts effortlessly. Its modular design and compatibility with standard pallet dimensions empower manufacturers to customize without compromising on speed or durability.

Maintenance routines are simplified through easy access components and clear diagnostics provided via the touchscreen interface, further reducing machine idle time.

Ultimately, the adoption of Zhengzhou Tuoyu’s Pallet Leg Nailing Machine symbolizes more than a mere equipment upgrade. It represents a crucial step towards transforming traditional, often fragmented pallet manufacturing lines into highly efficient, automated, and economically sustainable production systems.

By ensuring your production line switches from idle wait times to continuous operation with rapid adaptability, this solution unlocks new competitive advantages in a market where every minute counts.