In the competitive landscape of pallet manufacturing, productivity and precision dictate profitability. Traditional pallet leg nailing machines often fall short, hindered by limited automation and steep learning curves. This article delves into the game-changing technologies of Programmable Logic Control (PLC) systems paired with touchscreen operations—key drivers enabling manufacturers to leapfrog inefficiencies and realize consistent quality with minimal training.

Pallet production lines frequently grapple with downtime, manual errors, and slow adjustment processes. Conventional equipment demands extensive operator expertise, often leading to inconsistent nailing depth, improper leg alignments, and resultant product rejections. These challenges contribute to inflated labor costs and unpredictable throughput.

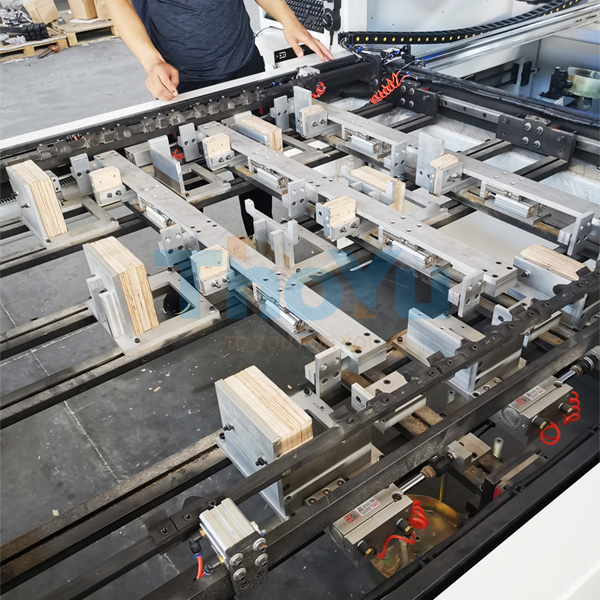

Integrating a PLC control system transforms operational reliability. PLCs precisely regulate nailing sequences, timing, and force to ensure uniform penetrations and secure leg attachments. Compared to analog controls, PLC-driven machines demonstrate up to 30% improvement in positional accuracy and significantly lower variance in nail depth. This stability translates to dramatically reduced scrap rates—up to 20% less material waste—and boosts overall line efficiency.

The introduction of user-friendly touchscreen human-machine interfaces (HMIs) empowers operators with intuitive control. Visual menus, real-time feedback, and programmable profiles enable rapid setup adjustments without complex coding. This ease of use condenses operator training from weeks to just three days, letting manufacturers “from entry-level to proficient in only 72 hours.”

Beyond automation, the machine offers both manual overrides and program-based adjustments, enabling maintenance teams to swiftly troubleshoot and recalibrate without halting production. This hybrid system balances flexibility with repeatability, allowing for tailored nailing protocols depending on pallet size and wood type.

The equipment supports standard pallet dimensions while also accommodating customization demands—a critical business differentiator. Its adaptable programming allows manufacturers to meet diverse client specifications efficiently, enhancing competitive positioning in both domestic and export markets.

The condensed training timeline not only minimizes onboarding downtime but accelerates return on investment. Operators gain confidence quickly, translating into fewer operational errors and higher throughput. This fusion of technology and usability exemplifies “making complexity simple and translating efficiency into visible results.”

| Metric | Traditional Machines | PLC-Controlled Machines | Improvement |

|---|---|---|---|

| Training Time | 10+ days | 3 days | -70% |

| Nailing Accuracy | 85% | >99% | +16% |

| Material Waste | 15% | 12% | -20% |

| Line Efficiency | 70% | 90% | +28% |

Manufacturers aiming to thrive in a demanding market must embrace digital transformation. Implementing a PLC-controlled pallet leg nailing machine with a touchscreen interface is more than an upgrade—it’s an operational revolution that empowers teams to “let complexity become simple and let efficiency become visible.”