In the dynamic pallet manufacturing industry, speed and efficiency are vital drivers of competitiveness. Many enterprises wrestle with steep learning curves and expensive downtime caused by complex machinery and lengthy operator training. Addressing these challenges head-on, Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has introduced its state-of-the-art pallet leg nailing machine — designed to empower pallet producers to rapidly master automated nailing and scale production with ease.

Unlike traditional pallet machinery, which can take weeks to operate proficiently, this innovative pallet leg nailing machine boasts a user-friendly interface and intelligent controls that enable operators to become fully productive within just three days. By minimizing training time, manufacturers can reduce overhead costs substantially while accelerating their time-to-market.

Key Benefit: Cutting training time by 70% translates directly into cost savings and less production downtime.

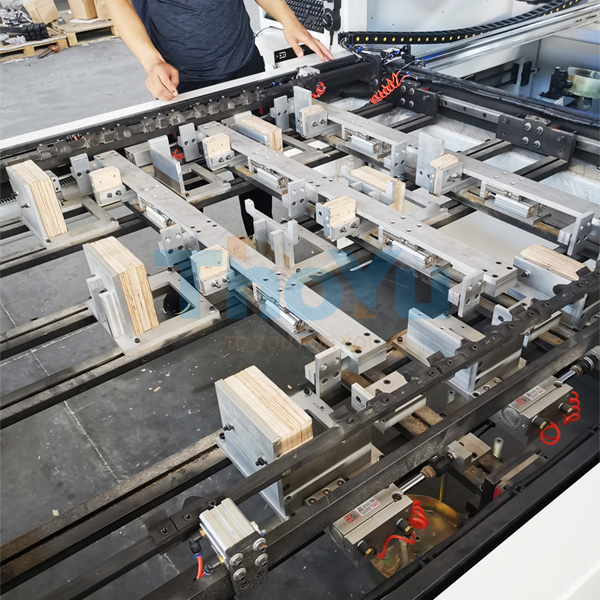

At the heart of the machine lies a robust PLC (Programmable Logic Controller) system coupled with an intuitive touch screen. This combination provides real-time monitoring and precise adjustments, allowing operators to switch between manual and automatic modes quickly. The system supports both standardized pallet specifications and tailor-made dimensions, catering to a wide range of manufacturing needs.

The automated nailing process significantly reduces cycle times, with this machine capable of boosting throughput by up to 30% compared to conventional methods. Meanwhile, its modular design simplifies maintenance, further minimizing unscheduled downtime.

A leading pallet manufacturing company in East China reported the following after integrating the pallet leg nailing machine:

These quantifiable improvements empower companies to handle growing order volumes without proportionally increasing labor costs, unlocking effective scalability.

In an industry challenged by fluctuating raw material costs and rising labor rates, automation is a strategic imperative. This pallet leg nailing machine serves as a catalyst for sustainable growth by:

By adopting this technology, pallet manufacturers can confidently navigate competitive pressures and tighten delivery schedules while improving overall manufacturing quality.