The pallet manufacturing industry has long been plagued by several persistent issues. Low production efficiency is a major headache for many businesses. Traditional manual or semi - automated processes often result in slow output, with some factories only able to produce around 200 - 300 pallets per day per production line. Moreover, the training of workers to operate pallet - making equipment is challenging. It usually takes about 2 - 3 weeks for new employees to become proficient in operating traditional machines, which not only increases labor costs but also causes delays in production. In addition, the maintenance of these machines is complex. Frequent breakdowns lead to significant downtime, sometimes up to 1 - 2 days per month, seriously affecting the overall production schedule.

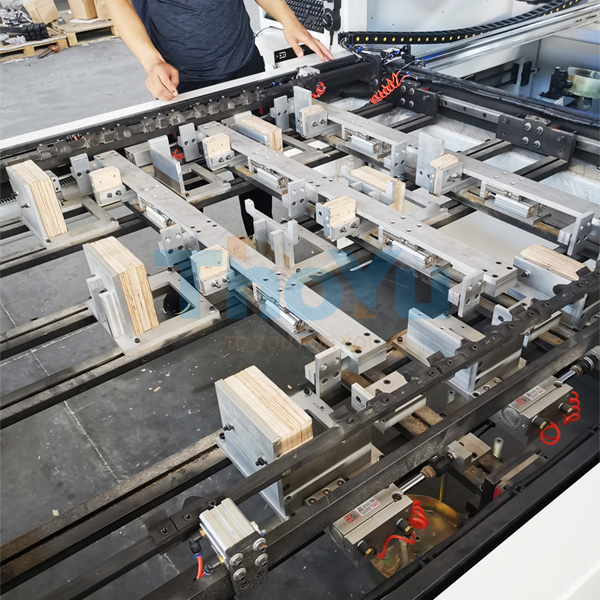

Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has introduced an automated pallet leg nailing machine that offers a revolutionary solution. Firstly, it features a user - friendly touch - screen operation. Workers can easily set parameters and control the machine through the intuitive interface, eliminating the need for complex button - pressing and programming. Secondly, it has a dual - adjustment mode of manual and program. This flexibility allows operators to make on - the - spot adjustments according to different production requirements. For example, when dealing with special - sized pallets, the manual mode can be used for fine - tuning. Thirdly, the machine has a simplified structure. Compared with traditional nailing machines, the number of parts has been reduced by about 30%, which not only makes it easier to maintain but also reduces the probability of breakdowns.

"Since we started using the pallet leg nailing machine from Zhengzhou Tuoyu, our production efficiency has skyrocketed. We used to produce 250 pallets per day, but now we can easily reach over 375 pallets per day, an increase of more than 50%. And the best part is that our new workers can start operating the machine proficiently in just three days!" - A satisfied customer from a pallet manufacturing company.

According to data from multiple customers, the use of this machine has significantly reduced downtime. The monthly downtime has been cut down to less than half a day. Also, the personnel training cycle has been shortened from 2 - 3 weeks to just 3 days, which greatly reduces labor costs and speeds up the production process.

Zhengzhou Tuoyu not only provides high - performance machines but also offers excellent customization services. They can adjust the machine's parameters and functions according to the specific needs of different customers, such as changing the processing size or the nailing pattern. In terms of reliability, the machine uses core components from top - notch brands like Schneider and Airtac. These high - quality parts ensure the long - term durability of the machine, with an expected service life of more than 10 years under normal use conditions.

The pallet leg nailing machine from Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. is a game - changer for the pallet manufacturing industry. By improving production efficiency by over 50%, reducing downtime, and shortening the training cycle, it helps businesses significantly cut costs. At the same time, its advanced technology and customization services enable enterprises to upgrade their production lines and move towards intelligent manufacturing. If you are looking for a reliable and efficient solution for your pallet production, don't miss out on this amazing machine. Click here to learn more about the pallet leg nailing machine