Intelligent Pallet Leg Nailing Machine Drives Efficiency in Pallet Manufacturing Industry

21 01,2026

Product description

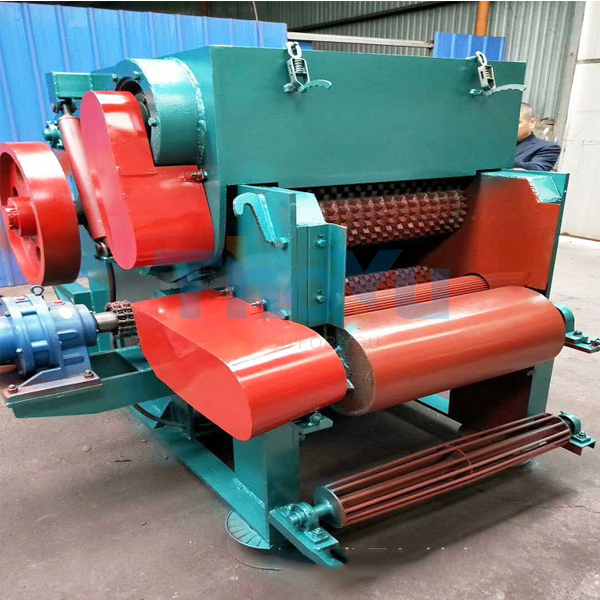

Facing intensifying competition in the pallet production sector, Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. introduces an intelligent pallet leg nailing machine that significantly enhances manufacturing efficiency and product quality. Featuring an advanced PLC control system, user-friendly touchscreen interface, and premium Schneider and Airtac components, the machine supports versatile customization and easy adjustments. Streamlined operation and reduced training time minimize downtime, enabling manufacturers to seize growth opportunities and expand market share. This article analyzes the equipment’s technical advantages, industry trends, and real-world applications, providing decision-makers with insights on leveraging smart machinery to boost competitiveness.

Advancing Pallet Manufacturing: The Rise of Intelligent Leg Nailing Machines

The pallet production industry is moving swiftly towards automation and digital integration as manufacturers face increasing competition and demand for higher quality and efficiency. In this evolving landscape, Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. offers its advanced pallet leg nailing machine, engineered to empower manufacturing enterprises with cutting-edge intelligent technology. This article explores how integrating PLC control systems and user-friendly interfaces into pallet manufacturing can dramatically boost productivity while reducing downtime and operational costs.

Industry Trends Shaping Pallet Production

Traditional pallet manufacturing has long relied on semi-automated processes prone to human error and inefficiencies. Contemporary market demands emphasize:

- Higher throughput rates to meet growing supply chain requirements.

- Consistent product quality to comply with international standards.

- Flexible customization capability for diverse client specifications.

- Reduced labor dependency and minimal machine downtime.

As a result, manufacturers adopting intelligent automation solutions demonstrate enhanced competitiveness and market agility.

Smart Features of the Pallet Leg Nailing Machine

The pallet leg nailing machine by Zhengzhou Tuoyu integrates several smart components and design innovations tailored for the pallet industry:

- Advanced PLC Control System: The programmable logic controller coordinates nailing cycles precisely, enabling consistent power, timing, and movement control. This significantly reduces rejects and rework.

- Intuitive Touchscreen Interface: Operators interact through a graphical HMI that simplifies parameter adjustments. This reduces the training curve by up to 40%, empowering skilled and novice workers alike.

- Premium Components from Schneider and Airtac: These reliable parts contribute to operational stability, extending mean time between failures (MTBF) and ensuring consistent production uptime.

- Modular & Compact Structure: The machine’s streamlined frame allows easy maintenance, fast part replacement, and adaptability to custom pallet sizes.

How the Equipment Enhances Operational Efficiency

Industry data reveals that integrating intelligent leg nailing machines can boost production efficiency by up to 30% and reduce machine downtime by nearly 25%. Here is how these improvements are realized:

- Simplified Operating Procedures: The user-friendly machine interface cuts operator errors, minimizing defective outputs.

- Shorter Training Duration: With visual controls and preset programs, new operators require less than 2 days training compared to traditional 3–5 days.

- Faster Changeovers: Quick adjustments make it easier to switch between different pallet designs, reducing non-productive time.

- Predictive Maintenance Built-In: Real-time alerts for component wear allow proactive servicing, preventing unexpected breakdowns.

Real-World Success Stories

One leading pallet manufacturer in Central China adopted Zhengzhou Tuoyu’s pallet leg nailing machine and reported remarkable results within the first 6 months:

| Metric |

Before Adoption |

After 6 Months |

| Daily Output (Pallets) |

1,200 |

1,560 (+30%) |

| Machine Downtime (%) |

12% |

9% (-25%) |

| Operator Training Time (Days) |

4 |

2 (-50%) |

This data underscores the machine’s tangible impact on operational efficiency, cost savings, and workforce agility.

Stay Competitive with Intelligent Automations

For pallet manufacturers striving to elevate productivity while maintaining product excellence, intelligent solutions such as the pallet leg nailing machine represent a breakthrough. By embracing automation tailored to industry needs, companies can seize market opportunities and strengthen supply chain positions.

Join the Conversation!

What challenges do you face in improving your pallet production line? Have you considered automation upgrades to reduce downtime? Share your experiences or questions below—let’s explore smarter manufacturing together.