Many pallet manufacturing enterprises often face efficiency bottlenecks. For example, a well - known European pallet manufacturer used to struggle with low - efficiency manual and semi - automatic nailing processes. Workers had to spend a lot of time adjusting nail positions and replacing nails, resulting in slow production speed and high labor costs. This situation is not unique but a common problem in the pallet manufacturing industry.

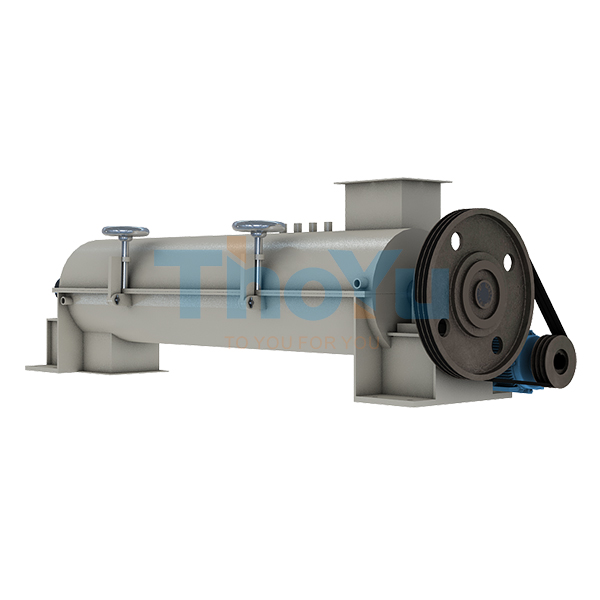

The pallet leg nailing machine launched by Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. is a game - changer. It is specifically designed for the production of European pallets and various pallet blocks. The highly automated design concept and reasonable structure are its prominent features. With a flexible manual and program adjustment function, it allows operators to choose according to different production needs. Whether it is a small - batch trial production or large - scale mass production, the machine can handle it with ease. Manual adjustment is as simple as turning a few knobs, and program control can be set up quickly through the intuitive interface, saving a lot of time and effort.

The core technology of this machine lies in its PLC control system and touch - screen operation. The PLC control system can precisely control every aspect of the nailing process, from the speed of the nail gun to the position of each nail. The touch - screen operation provides a user - friendly interface, enabling operators to easily customize the nailing parameters according to different pallet specifications. Moreover, the machine offers a high degree of customization. For example, different nail gun configurations can be selected according to the thickness and hardness of the pallet materials, ensuring the nail position is accurate and stable every time. This kind of professional customization function is rarely seen in traditional pallet nailing equipment.

Let's take a look at some real - world applications. A large - scale pallet manufacturing enterprise in Asia adopted this pallet leg nailing machine. Before using the machine, their daily production of European pallets was about 500 pieces, with a high defect rate of about 5%. After introducing the new machine, the daily production increased to 1200 pieces, and the defect rate dropped to less than 1%. Another medium - sized factory in South America also experienced a similar efficiency boost. They used to produce 300 pallet blocks per day, but after using the machine, the production volume reached 800 pieces per day. These real - world cases clearly demonstrate the machine's ability to significantly improve production efficiency.

Compared with traditional pallet nailing processes, this machine has obvious advantages. Traditional processes often rely on manual labor, which is not only time - consuming but also prone to human errors. The nail positions may vary, and the production speed is limited. In contrast, the pallet leg nailing machine of Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. can ensure consistent nail positions, high - speed production, and low defect rates. In terms of cost, although the initial investment in the machine is relatively high, in the long run, it can save a large amount of labor costs and reduce waste caused by defective products.

We encourage you to share your thoughts and experiences in the comments section below. If you are a pallet production enterprise looking for ways to improve efficiency, this pallet leg nailing machine is definitely worth considering. It can help you simplify operations, reduce costs, and improve product quality. Don't miss this opportunity to transform your pallet production process. Click here to learn more about the pallet leg nailing machine