In the tray manufacturing industry, traditional production methods have long been plagued by low efficiency and high costs, hindering the development of enterprises. Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has introduced a game - changing solution: the CNC double - station tray nailing machine. This article will delve into how this machine helps tray manufacturing enterprises reduce costs and increase efficiency, thereby promoting the high - efficiency development of the industry.

The tray manufacturing industry has faced significant challenges in terms of efficiency and cost. Traditional production methods often require a large number of operators and long working hours, resulting in high labor costs. Moreover, the low precision and high defect rate in traditional production not only increase material waste but also reduce overall productivity. These issues have become bottlenecks for the development of tray manufacturing enterprises.

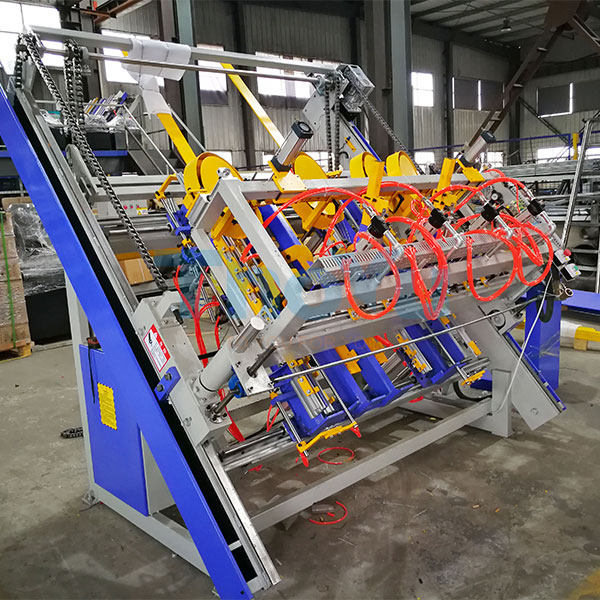

The double - station design of the CNC double - station tray nailing machine is one of its key selling points. With this design, the machine can operate on two trays simultaneously, greatly improving production efficiency. A well - known industry expert once said, "The double - station design is a revolutionary improvement in tray manufacturing, which can effectively double the production capacity in the same time frame."

Not only that, this machine is capable of producing high - quality trays that meet European and American standards. It has an extremely low defect rate, which means less waste of materials and lower production costs. In fact, the defect rate of this machine is less than 1%, far lower than the industry average of about 5%.

The machine is equipped with powerful automation functions, such as automatic stacking and finished product flipping. These functions optimize the production process and reduce the need for manual intervention. For example, the automatic stacking function can neatly stack the finished trays, saving storage space and facilitating subsequent handling. The finished product flipping function can ensure that the trays are in the correct orientation for packaging or further processing.

Specific data shows that with the help of these automation functions, only three operators are needed to produce 1000 high - precision trays in 8 hours. In contrast, traditional production methods may require 8 - 10 operators to achieve the same output, which shows a significant improvement in labor efficiency.

The machine uses advanced Japanese and German components, which ensure its stability and durability. In addition, it is equipped with a safety protection mechanism, such as a fault - safe system. This system can automatically detect and stop the machine in case of any abnormal situation, ensuring the safety of operators and the integrity of the machine. According to statistics, the machine's failure rate is less than 3% over a one - year period, which is much lower than other similar products in the market.

One of the outstanding features of this machine is its customization ability. It can be adjusted according to different tray sizes, nail types, and production requirements. This means that it can meet the diverse needs of the global market, whether it is for small - scale local production or large - scale industrial manufacturing.

Many tray manufacturing enterprises have already benefited from this machine. For example, a company in the United States increased its production efficiency by 80% after using this machine, and at the same time, reduced its production cost by about 30%. Industry experts have also given high praise to this machine. A senior engineer in the tray manufacturing industry said, "The CNC double - station tray nailing machine is a milestone in the industry, which will lead the industry towards a more efficient and automated future."

In the context of the rapid development of the global manufacturing industry, the tray manufacturing industry is also constantly evolving. The trend of automation and intelligence is becoming more and more obvious. The CNC double - station tray nailing machine is in line with this trend, which not only helps enterprises solve current problems but also prepares them for future challenges.

If you are interested in learning more about how this machine can transform your tray manufacturing business and achieve cost - reduction and efficiency - improvement, please click here.

We would like to invite you to share your tray manufacturing experience. Have you encountered similar efficiency and cost challenges in your production process? How did you solve them? Share your stories in the comments below!