In the tray production industry, companies are constantly seeking ways to improve efficiency and reduce costs. Currently, many tray manufacturers are facing challenges such as low production efficiency and high labor costs. According to industry research, traditional tray production methods often result in a production efficiency of only about 60% - 70%, and labor costs can account for up to 30% - 40% of the total production cost. This has become a major bottleneck for the development of the industry, making digital transformation an urgent need.

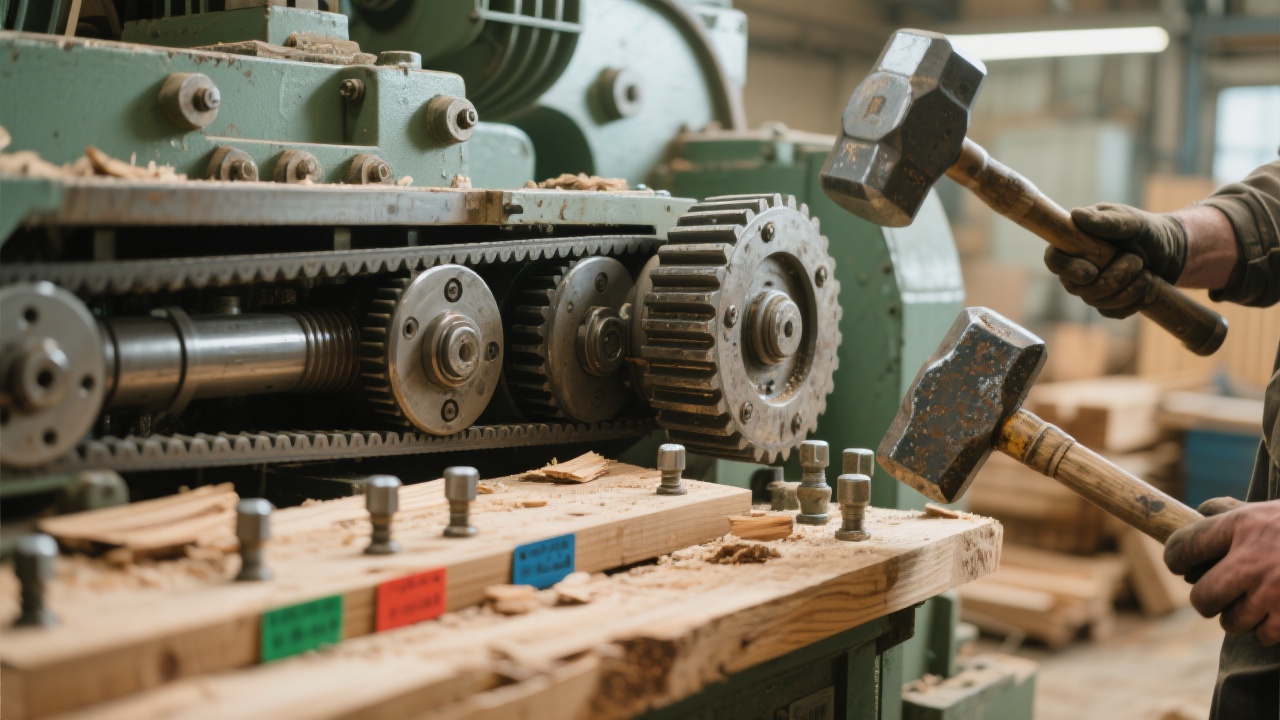

Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has developed a tray block cutting saw (multi - blade model) to address these issues. This cutting saw has core functions that are well - suited for a variety of application scenarios in tray production. Its fully automatic feeding and discharging system is a game - changer. By automating the feeding and discharging processes, it can significantly optimize the production workflow. For example, in a traditional production line, it may take 3 - 4 workers to complete the feeding and discharging tasks, but with the fully automatic system of this cutting saw, only 1 worker is needed for simple supervision. This reduces the labor input by about 70% and also improves the production consistency and stability.

The technical features of the cutting saw are also remarkable. It offers different saw blade configurations to meet various production requirements. The saw blades are made of high - quality materials, which can ensure high - precision cutting. For instance, with a specific saw blade configuration, the cutting accuracy can reach an error range of less than ±0.5mm. In terms of production volume, compared with traditional cutting equipment, this cutting saw can increase the daily production volume by 50% - 80%. Some production data shows that a company using this cutting saw increased its daily tray block production from 500 pieces to 800 - 900 pieces.

Real - world customer reviews further demonstrate the advantages of this equipment. A tray manufacturing company in Guangdong reported that after using this cutting saw, their production efficiency increased by 65%, and the defective product rate decreased from 5% to 1%. Another customer in Shandong mentioned that the automatic feeding and discharging system not only saved labor but also improved the overall safety of the production process. In a market comparison analysis, compared with similar products on the market, this cutting saw has better performance in terms of cutting quality, production efficiency, and cost - effectiveness. Its unique features and functions give it a strong competitive edge.

Looking at the digital trend in tray production, the future of equipment is moving towards more intelligent and automated directions. For example, future cutting saws may be equipped with more advanced sensors and control systems to achieve real - time monitoring and adjustment of the cutting process. They may also be integrated with the factory's overall production management system to realize more efficient resource allocation and production scheduling. Zhengzhou Tuoyu's tray block cutting saw is a step in this digital transformation journey, providing a reliable solution for tray manufacturers to improve efficiency, reduce costs, and achieve intelligent upgrades.

For industry managers and equipment procurement decision - makers, understanding the advantages and potential of this equipment is crucial. By choosing the right cutting equipment, companies can not only solve current production problems but also gain a head start in the digital transformation of the industry. Are you facing similar challenges in your tray production? Click here to learn more about how this equipment can transform your production process and get 3 industry - specific solution cases.