In the pallet manufacturing industry, efficiency and cost-effectiveness are crucial factors. The high-speed blade drum wood chipper has emerged as a revolutionary solution to address the existing pain points. Let's explore how this advanced equipment can transform the pallet manufacturing process.

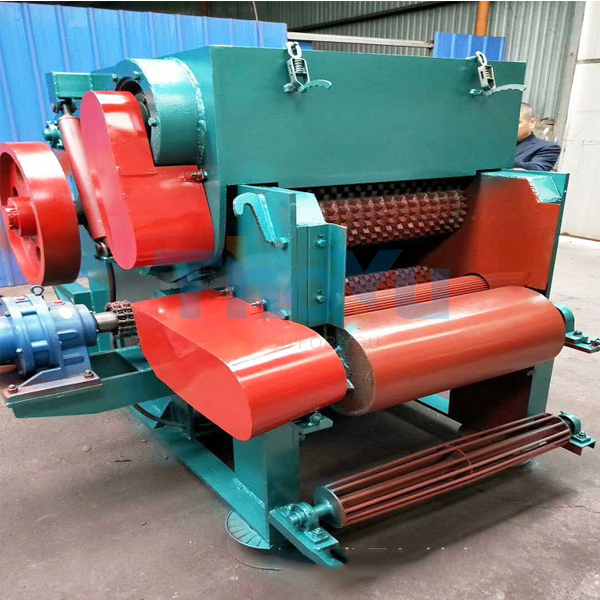

The high-speed blade drum wood chipper is equipped with several core technological features. Firstly, its unique rotor structure is designed to ensure a smooth and efficient chipping process. The blades on the rotor are made of high-quality materials, providing sharp cutting edges that can handle various types of wood with ease. This design reduces the force required for chipping, thus saving energy.

Secondly, the hydraulic buffer system plays a vital role. It helps to absorb the shock generated during the chipping process, protecting the machine from excessive wear and damage. This not only extends the service life of the equipment but also reduces maintenance costs.

Another important feature is the reverse feeding protection. In case of any blockage or abnormal situation, the machine can automatically reverse the feeding direction, preventing damage to the blades and ensuring the safety of the operators.

Compared with traditional wood chippers, the high-speed blade drum wood chipper showcases significant advantages in terms of manpower, energy consumption, and maintenance. Traditional machines often require more operators to feed and operate, while this advanced chipper can be operated with less manpower, saving labor costs.

In terms of energy consumption, the high-speed blade design and efficient rotor structure enable the machine to process 5 - 20 tons of wood per hour with relatively low energy input. This is a remarkable improvement compared to traditional chippers, which consume more energy to achieve the same output.

Maintenance is also a major concern. Traditional chippers may require frequent blade replacements and complex maintenance procedures. However, the high-speed blade drum wood chipper features a "change blades quickly and save on repairs" design. The blades are easy to replace, and the overall maintenance process is simplified, reducing downtime and maintenance costs.

Let's take a look at some real - world examples to illustrate the cost - saving potential of this equipment. One pallet manufacturing factory replaced its traditional wood chippers with high - speed blade drum wood chippers. As a result, they were able to cut their annual labor costs by $30,000. This was mainly due to the reduced need for operators and the improved efficiency of the new machines.

"Since we installed the high - speed blade drum wood chippers, our production process has become much more streamlined. We've seen a significant reduction in costs and an increase in productivity," said the factory manager. This customer feedback clearly shows the positive impact of the equipment.

One of the outstanding features of the high - speed blade drum wood chipper is its ability to be customized. The screen size is adjustable, which means it can meet the different requirements of various raw materials. Whether you are dealing with softwood or hardwood, or different sizes of wood pieces, the machine can be adjusted to produce the desired wood chips.

This customization feature greatly enhances the applicability of the equipment. It allows pallet manufacturers to use a wider range of raw materials, reducing the dependence on specific types of wood and increasing the flexibility of the production process.

In the current industrial landscape, green production and intelligent manufacturing are the prevailing trends. The high - speed blade drum wood chipper is designed with these trends in mind. It consumes less energy, which is in line with the concept of green production. Additionally, with its advanced control system and automation features, it is moving towards the direction of intelligent manufacturing.

In conclusion, the high - speed blade drum wood chipper offers an all - in - one solution for the pallet manufacturing industry. With its advanced technology, cost - effectiveness, customization capabilities, and forward - looking design, it is the ideal choice for pallet manufacturers looking to upgrade their equipment. If you are interested in learning more about how this equipment can transform your pallet manufacturing process, click here to discover more!

Question for interaction: Have you ever considered upgrading your wood chipping equipment in your pallet manufacturing factory? What are your main concerns?