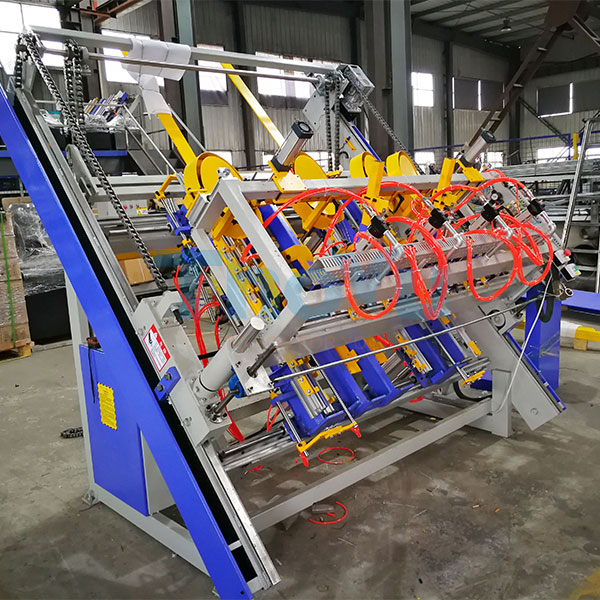

In today's highly competitive industrial landscape, optimizing production processes and enhancing efficiency are crucial for businesses aiming to stay ahead. Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has developed an innovative solution - the Fully Automatic Multi - layer Plywood Pallet Block Machine. This article delves into the top five reasons to choose this high - precision automated equipment and its applications across various industries.

The fully automatic multi - layer plywood pallet block machine from Zhengzhou Tuoyu utilizes advanced technology to streamline the production process. With an automated control system, it can handle complex operations with ease. For example, through precise programming, the machine can automatically cut, shape, and assemble the plywood pieces into pallet blocks. According to market research, traditional manual production methods can only produce about 50 - 80 pallet blocks per hour, while this automated machine can reach a production rate of 150 - 200 pallet blocks per hour, significantly improving production efficiency.

Precision is a key factor in pallet block production. This machine is designed to ensure high precision in every step of the production process. It uses high - end sensors and control algorithms to maintain strict tolerances, resulting in pallet blocks with consistent dimensions and quality. In a case study of a logistics company, after switching to this machine, the rejection rate of pallet blocks decreased from 5% to less than 1%, greatly reducing waste and improving overall product quality.

One of the outstanding advantages of this machine is its ability to support customized production. Different industries have different requirements for pallet blocks in terms of size, shape, and load - bearing capacity. The machine can be easily adjusted to meet these diverse needs. For instance, an e - commerce company needed special - sized pallet blocks for its new warehousing system. Zhengzhou Tuoyu's machine was able to quickly adapt to the new specifications, enabling the company to smoothly implement its new logistics plan.

The machine is equipped with components from top domestic brands and an intelligent operating system. These reliable components and the intelligent system work together to ensure long - term stable operation. The intelligent system can monitor the machine's operation in real - time, detect potential problems in advance, and even perform self - diagnosis and self - repair in some cases. A manufacturing company reported that after using this machine for a year, the downtime due to mechanical failures decreased by 80%, ensuring continuous production.

From a customer's perspective, this machine brings significant cost savings. By reducing labor costs, waste, and downtime, companies can lower their overall production costs. In addition, the high - quality and customizable pallet blocks produced by this machine can help companies enhance their competitiveness in the market. A furniture manufacturing company was able to reduce its pallet block production cost by 30% after adopting this machine, which allowed it to offer more competitive prices to its customers and gain a larger market share.

This machine has a wide range of applications in different industries. In the logistics and warehousing industry, it can help build more efficient storage systems. In the manufacturing industry, it can support the production of high - quality products by providing reliable pallet blocks. In the e - commerce industry, it can meet the needs of rapid and large - scale order processing.

Are you interested in enhancing your pallet block production level and intelligent warehousing logistics capabilities? Click here to learn more about how Zhengzhou Tuoyu's fully automatic multi - layer plywood pallet block machine can revolutionize your business!

We'd love to hear your thoughts. Do you have any questions or experiences related to pallet block production? Leave a comment below and let's start a conversation!