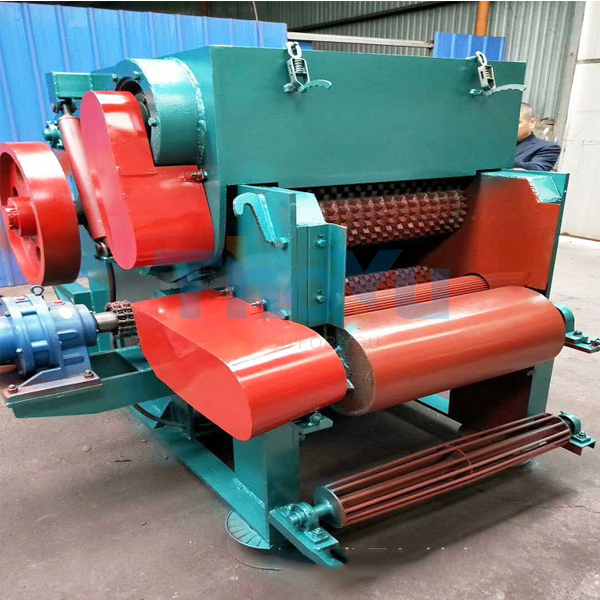

In the realm of wood processing, finding the right equipment is crucial for pallet manufacturing plants aiming to boost efficiency and cut costs. Today, we're diving into a game - changer: the high - efficiency drum wood chipper, and how it stacks up against traditional wood chippers.

This article is tailored for pallet factory owners and procurement decision - makers. You're constantly on the lookout for ways to enhance your production line, and the high - efficiency drum wood chipper might just be the solution you've been waiting for.

The high - efficiency drum wood chipper stands out with several remarkable features. First and foremost, it boasts high productivity. Unlike traditional chippers, this machine can process 5 - 20 tons of wood per hour. That's right, 1 machine can replace 3 traditional chippers, which means a significant reduction in labor and time costs. In fact, it can save up to 60% of labor, allowing you to reallocate your workforce to other important tasks.

Another key advantage is its ease of maintenance. The structure of this chipper is simple, and the hydraulic system is stable. It also comes with a reverse feeding protection mechanism, ensuring the safety of the equipment and operators. The screen can be customized according to your specific needs, providing flexibility in production.

Let's look at the numbers. With an hourly processing capacity of 5 - 20 tons, this chipper can handle large volumes of wood. The ability to replace 3 traditional chippers not only saves on equipment costs but also on the floor space in your factory. And with a labor savings of up to 60%, you can see a direct impact on your bottom line.

As environmental policies become stricter, there is a growing demand for energy - efficient and high - performance equipment in the wood processing industry. The high - efficiency drum wood chipper fits the bill perfectly. It is designed to be energy - efficient, helping your factory meet environmental requirements while also improving productivity.

Take, for example, a wood chip factory that recently switched to the high - efficiency drum wood chipper. Before the switch, they were struggling with low productivity and high labor costs. After installing the new chipper, their production capacity increased by 150%, and they were able to reduce their labor force by half. The factory also reported a significant reduction in equipment downtime, thanks to the easy - to - maintain design of the chipper.

Users of the high - efficiency drum wood chipper rave about its user - friendly features. Changing blades is a quick process, taking only about 15 minutes compared to hours with traditional chippers.检修 is also a breeze, with minimal downtime. The machine runs smoothly, with a very low failure rate, ensuring continuous production in your factory.

In conclusion, the high - efficiency drum wood chipper is a revolutionary product for pallet manufacturing plants. It offers high productivity, easy maintenance, and a great user experience.告别低效老设备,开启智能削片新时代!(Say goodbye to inefficient old equipment and embrace the new era of intelligent wood chipping!)

We encourage you to share your current production pain points or ask questions about the technical details in the comments section below. Are you ready to take your factory's productivity to the next level? Click here to learn more about the high - efficiency drum wood chipper