As the global demand for wooden pallets continues to rise, manufacturers are under increasing pressure to enhance productivity while maintaining cost-effectiveness. In this context, the drum wood chipper has emerged as a reliable and high-performance solution that significantly improves production efficiency in the pallet manufacturing industry.

The modern pallet manufacturing industry is driven by the need for faster processing, reduced labor costs, and improved material utilization. Traditional wood chipping methods often struggle to meet these demands due to their limited capacity and inefficient operation. According to recent industry data, the average wood processing capacity of traditional machines ranges from 1 to 5 tons per hour. In contrast, the drum wood chipper can process between 5 to 20 tons of raw material per hour, making it an ideal choice for large-scale operations.

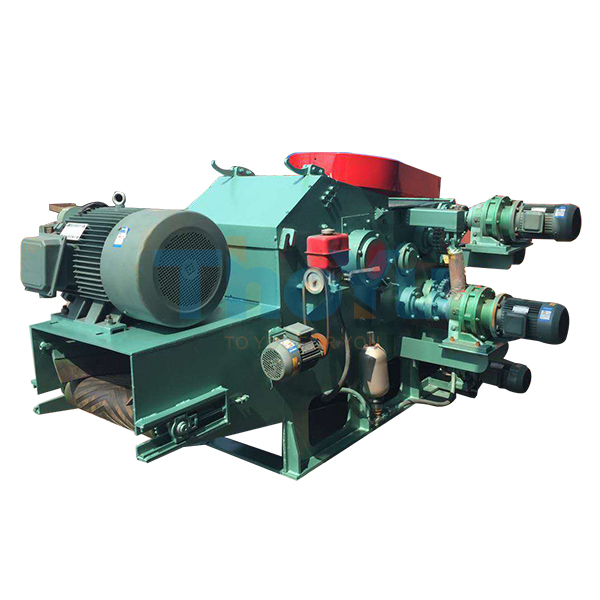

The drum wood chipper is designed with advanced engineering principles to ensure efficient and stable performance. Its compact structure allows for easy installation and maintenance, while its modular design enables quick replacement of parts when needed. The machine also supports customizable screen sizes, allowing manufacturers to adapt to different wood types and production requirements. This flexibility makes it suitable for a wide range of applications, from small-scale workshops to large industrial facilities.

Compared to conventional wood chippers, the drum model offers significant advantages. For example, one unit of the drum wood chipper can replace up to three traditional machines, reducing both capital investment and operational complexity. Additionally, the energy consumption of the drum wood chipper is lower by approximately 30%, which translates into long-term cost savings for manufacturers.

| Feature | Traditional Chipper | Drum Wood Chipper |

|---|---|---|

| Processing Capacity (ton/hour) | 1–5 | 5–20 |

| Energy Consumption (kW/h) | 15–25 | 10–18 |

| Maintenance Frequency | High | Low |

Several leading pallet manufacturers have already adopted the drum wood chipper and reported remarkable improvements in their production processes. One such company, based in Southeast Asia, saw a 40% increase in output after replacing its old equipment with the new model. Another manufacturer in Europe reduced its labor costs by 25% and achieved better material consistency, which enhanced the quality of their final products.

In addition to boosting efficiency, the drum wood chipper contributes to environmental sustainability. Its optimized cutting mechanism minimizes wood waste and reduces energy usage, aligning with global trends toward green manufacturing. Furthermore, the machine’s low maintenance requirements and long service life further reduce total ownership costs for users.

The drum wood chipper is particularly suitable for companies involved in the production of wooden pallets, furniture components, and other wood-based products. It is recommended for businesses looking to scale up their operations or upgrade existing systems. To maximize benefits, manufacturers should consider factors such as wood type, desired output, and space availability before selecting the appropriate model.

For more information about how the drum wood chipper can help your business achieve higher productivity and lower costs, we invite you to explore our full product range today. Discover the power of advanced technology in transforming your production line.