In the manufacturing of plywood pallets, traditional methods often face numerous challenges. Manual operations lead to low efficiency, with an average production speed of only about 10 - 15 pallets per hour. Moreover, the quality consistency is poor, and the defect rate can reach up to 10%. Additionally, labor-intensive production results in high labor costs, which account for approximately 30 - 40% of the total production cost. The Zhengzhou Tuoyu Electromechanical's fully automatic multi-layer plywood pallet block making machine addresses these pain points with its advanced features.

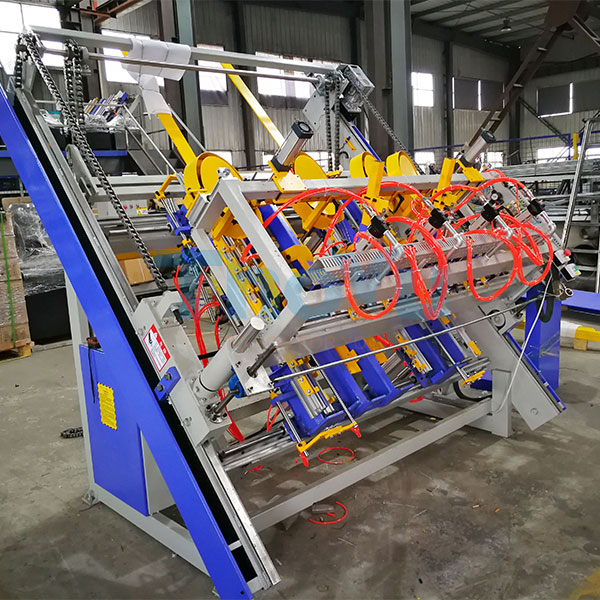

This machine is equipped with high - precision molds and intelligent control systems. It can precisely control the pressure, temperature, and time during the production process, ensuring the quality of each pallet is consistent. The core function of the machine lies in its ability to automate the entire production process, from raw material feeding to finished product output.

The automation process of the fully automatic multi - layer plywood pallet block making machine brings significant improvements in both efficiency and quality. In terms of efficiency, the machine can produce up to 30 - 40 pallets per hour, which is a 2 - 3 times increase compared to traditional manual methods. This means that factories can meet larger orders in a shorter time.

Regarding quality, the automation process reduces human errors. The defect rate drops to less than 2%, ensuring that most of the pallets produced meet high - quality standards. The following information chart shows the comparison between the traditional production process and the automated production process:

| Production Process | Production Speed (pallets per hour) | Defect Rate |

|---|---|---|

| Traditional Manual | 10 - 15 | 10% |

| Automated | 30 - 40 | Less than 2% |

Let's take a look at some real - world customer application cases. An international logistics company was facing the problem of high pallet procurement costs and inconsistent quality. After using the fully automatic multi - layer plywood pallet block making machine from Zhengzhou Tuoyu Electromechanical, they were able to produce their own pallets with high quality and at a lower cost. The company's logistics efficiency improved by 20% due to the standardized pallets.

"Since we started using this machine, our production efficiency has increased significantly, and the quality of pallets has become much more stable. It has saved us a lot of costs and improved our competitiveness in the market." - A manager from the international logistics company

Zhengzhou Tuoyu Electromechanical's machine has strong customization ability. It can be adjusted according to different customer requirements, such as the size, thickness, and load - bearing capacity of the pallets. This flexibility allows the machine to meet the diverse needs of different industries.

In addition, the machine uses high - reliability domestic components. These components have undergone strict quality inspections and have a long service life. The use of domestic components also ensures fast after - sales service and lower maintenance costs. Compared with imported components, the cost of domestic components is about 20 - 30% lower, which further reduces the overall cost of the machine.

The intelligent operating system of the machine is one of its key features. It has a user - friendly interface that allows operators to easily set parameters and monitor the production process. The system can automatically adjust the production parameters according to the real - time situation, ensuring the stability of the production process.

Even operators with little experience can quickly master the operation of the machine. The intelligent system also has functions such as fault diagnosis and alarm, which can help maintenance personnel quickly locate and solve problems, reducing the downtime of the machine.

By using the fully automatic multi - layer plywood pallet block making machine, enterprises can enhance their sustainable competitiveness. The improvement in efficiency and quality allows enterprises to reduce costs and improve product quality, which is crucial for winning more market shares. The ability to produce customized pallets also enables enterprises to meet the special needs of customers, further expanding their customer base.

In conclusion, the fully automatic multi - layer plywood pallet block making machine from Zhengzhou Tuoyu Electromechanical is a powerful tool for enterprises to achieve automated production transformation. If you want to make every pallet precise and take your factory into the intelligent future, click here to learn more.

We welcome your comments and questions. Leave a message below to share your thoughts or ask about any concerns you may have regarding the machine.