Manufacturers and logistics providers increasingly demand production lines that elevate quality, optimize throughput, and reduce operational costs. The fully automatic multi-layer plywood pallet block machine developed by Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. stands out as an industry game-changer. Leveraging advanced automation and intelligent control, this equipment not only ensures high precision and uniformity but also significantly boosts production efficiency.

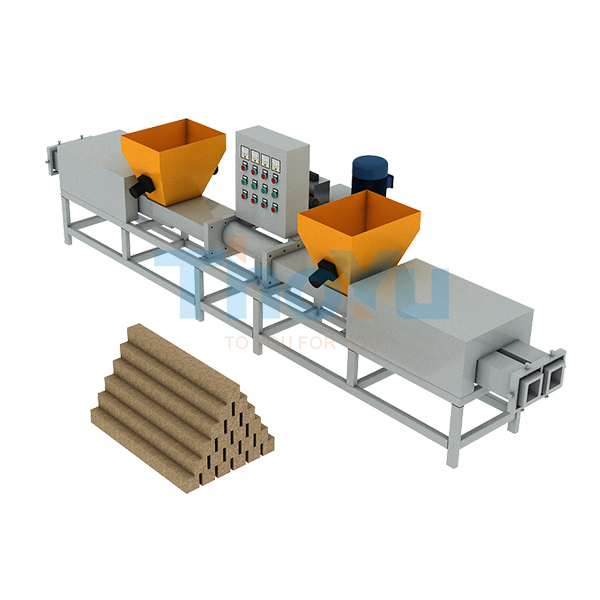

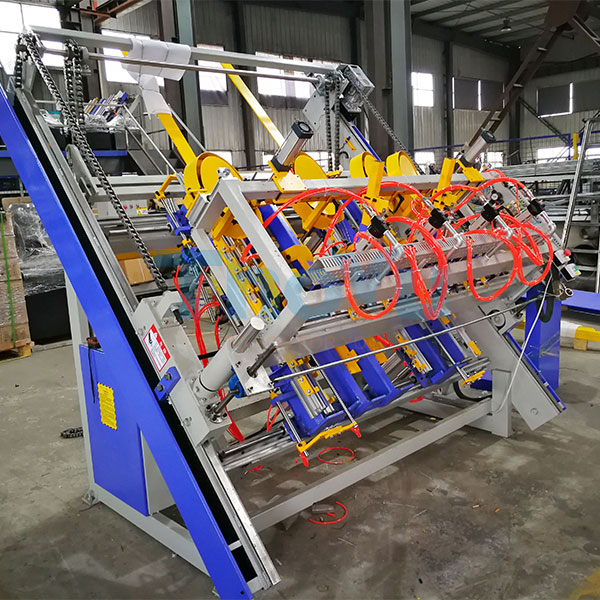

At the heart of the machine lies its automated multi-layer assembly process, minimizing manual intervention and human error. Featuring an intelligent operating system with real-time monitoring and adaptive control, the machine can sustain a stable production rate exceeding 120 pallet blocks per hour. High-precision sensors and quality inspection modules guarantee that product dimensional tolerances remain within ±0.5 mm, fostering consistency critical for downstream warehouse automation.

The equipment’s modular design allows for customization to meet varying customer specifications — from block dimensions to adhesive application methods. Moreover, premium components sourced from industry-leading suppliers underpin the machine's robust longevity and stability, drastically reducing downtime and maintenance costs.

A leading warehousing solutions provider integrated this pallet block machine into their operations and reported a 38% increase in overall production efficiency within the first quarter. The automated system minimized labor costs by reducing workforce requirements by up to 25%, while product defects saw a sharp decline from 4.5% to below 0.7%. These improvements translated into tangible cost savings and faster order fulfillment cycles.

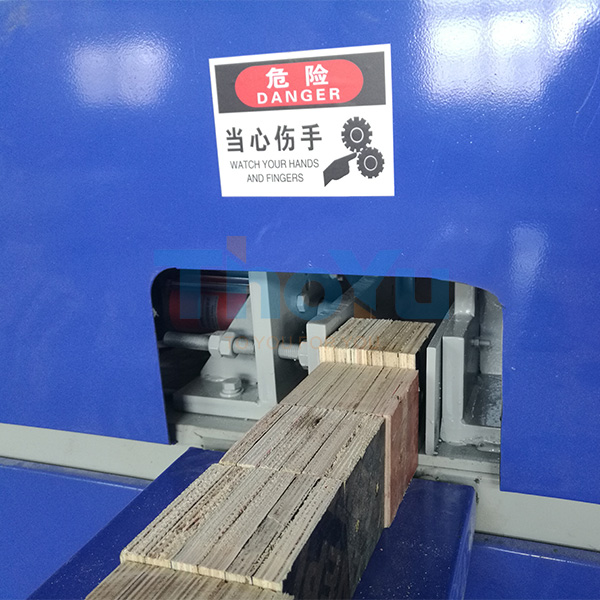

Another manufacturing client praised the machine’s precise glue application technology, which enhanced the bonding strength of multi-layer plywood blocks, extending pallet lifespan by 20%. This improvement also contributed to fewer replacements and improved sustainability performance — a competitive advantage highly valued in international supply chains.

Compared to conventional manual or semi-automatic assembly processes, the fully automated solution virtually eliminates inconsistencies caused by human factors. This yields improved batch uniformity and faster cycle times. It also integrates seamlessly with existing logistics automation, enabling end-to-end digital workflow within manufacturing and warehousing environments.

The ability to program customized production parameters ensures flexibility to adapt rapidly to evolving market demands, while reducing waste in materials and energy. Data analytics embedded in the system provide actionable insights for continuous improvement.

Understanding that each client’s operational context differs, Zhengzhou Tuoyu prioritizes tailored customization. Intelligent control algorithms are calibrated to handle various plywood types, adhesive viscosities, and layer thicknesses, ensuring optimal performance regardless of inputs. This versatility supports businesses in diverse sectors—from heavy manufacturing to fast-moving consumer goods logistics.

Reliable spare parts supply and responsive technical support further secure clients' long-term investment, facilitating uninterrupted production cycles and empowering sustainable business expansion.

We invite manufacturing leaders and logistics managers to engage—how have automation solutions reshaped your production? What challenges remain in pallet block fabrication? Share your questions or experiences to fuel industry-wide knowledge exchange and innovation.