The fully automatic multi - layer plywood pallet block machine from Zhengzhou Tuoyu Electromechanical Co., Ltd. offers a revolutionary approach to plywood pallet production. From the moment the raw materials are fed into the machine to the final cutting process, every step is automated. This significantly reduces the need for manual intervention, allowing manufacturers to streamline their operations and focus on other aspects of their business. For example, in a traditional plywood pallet production line, workers would have to manually handle materials at each stage, which is not only time - consuming but also prone to errors. With this automated machine, the entire process is smooth and efficient, ensuring a consistent output quality.

Let's take a look at a real - life example of a European wood product factory. Before using the Zhengzhou Tuoyu Electromechanical's machine, the factory had a relatively low production capacity. The manual operation led to inconsistent product quality, and the energy consumption was relatively high. However, after introducing this automated pallet block machine, the results were astonishing. The production capacity increased by 40%, which means the factory can produce more products in the same amount of time. The good product rate also improved from 80% to 95%, indicating a significant reduction in waste. Moreover, the energy consumption decreased by 20%, leading to substantial cost savings. As the factory manager said, "This machine has truly transformed our production process. It's like injecting new life into our factory."

"This machine has truly transformed our production process. It's like injecting new life into our factory." - Factory Manager, European Wood Product Factory

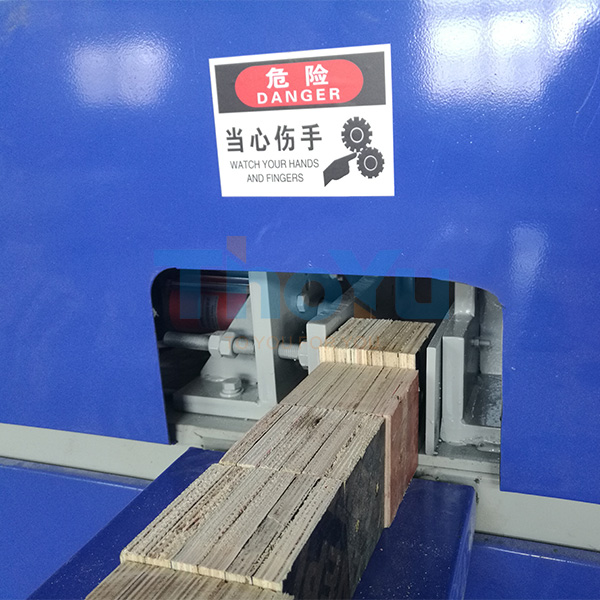

One of the key features of this machine is its high - precision control system. It can accurately control every aspect of the production process, from the speed of the conveyor belt to the depth of the cutting blade. This ensures that each pallet block is cut to the exact specifications, with a tolerance of less than ±0.5mm. Additionally, the machine comes with customizable parameter settings. Manufacturers can adjust the machine according to their specific production requirements, whether it's the size of the pallet block, the thickness of the plywood, or the cutting pattern. The use of high - quality domestic components also guarantees the reliability of the machine. These components are designed to withstand long - term use and harsh working conditions, reducing the frequency of breakdowns and maintenance costs.

The automated pallet block machine is highly adaptable to various industries. In the furniture industry, it can be used to produce high - quality pallet blocks for transporting and storing furniture components. In the logistics and packaging industries, the machine can quickly produce pallet blocks that meet different load - bearing requirements. Its flexible production capacity allows it to switch between different production tasks easily, making it an ideal choice for manufacturers who need to produce a variety of products. For example, a furniture manufacturer may need to produce different sizes of pallet blocks for different furniture models, and this machine can handle such requirements with ease.

The intelligent system of this machine is another major advantage. It features an integrated operation interface that simplifies the operation process. Workers can easily monitor and control the machine's operation through this interface, which also provides real - time data on production status, such as the number of products produced, the running speed of the machine, and any potential faults. This not only improves the stability of the machine's operation but also makes maintenance more convenient. If a problem occurs, the system can quickly identify the location and nature of the fault, allowing maintenance personnel to take timely measures.

When comparing the automated production of this machine with traditional manual processes, the differences are obvious. In traditional manual production, workers need to perform each step of the process manually, which is labor - intensive and time - consuming. The quality of the products also varies greatly depending on the skill level of the workers. In contrast, the automated production of this machine ensures high efficiency and consistency. The production speed is much faster, and the quality of each product is the same, meeting the strict quality standards of modern manufacturing. For example, in a manual production line, it may take a worker several minutes to produce one pallet block, while the automated machine can produce several blocks in the same time.

Upgrade Your Production with Our Automated Pallet Block Machine Now!