With increasing global emphasis on sustainable practices and resource efficiency, the waste wood recycling industry faces pivotal challenges. Efficiently converting scrap wood into high-quality pallets is no longer optional—it’s a necessity. Addressing these pressing demands, Zhengzhou Tuoyu Mechanical & Electrical Equipment Co., Ltd. has innovated a groundbreaking solution: the Dual-Mode Pressing Wood Pallet Machine.

In the realm of waste wood recycling, businesses often grapple with inconsistent product quality, slow production speeds, and high operational costs. Traditional wood pallet manufacturing equipment typically falls short in automation and safety features, resulting in suboptimal daily outputs ranging from 50 to 120 pallets with labor-intensive processes. Environmental regulations and growing customer demand for sustainable packaging amplify the pressure for efficient, eco-friendly solutions.

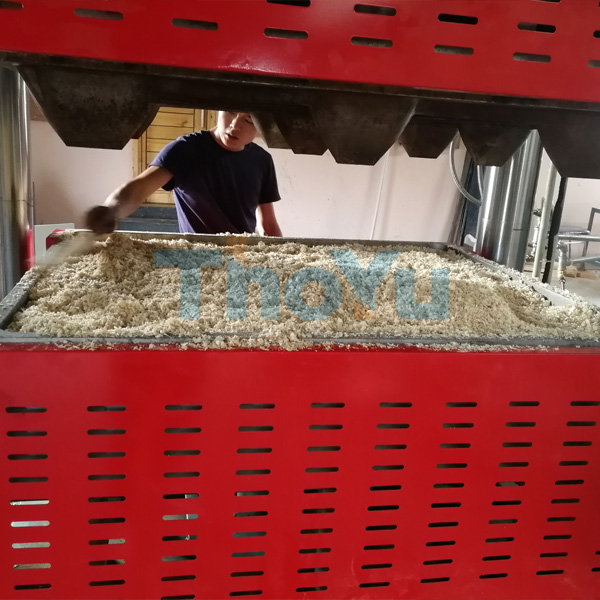

At the heart of this innovation lies a robust four-column hydraulic structure intelligently engineered to ensure stability, uniform pressure distribution, and extended service life. This foundation is paired with an advanced automatic control system that offers precision process management, minimizing human error and maximizing productivity.

Comprising industry-leading safety protection devices, including emergency stop functions, hydraulic overload safeguard, and automatic fault diagnosis, the machine guarantees operator safety while maintaining uninterrupted production flow.

| Feature | Specification | Benefit |

|---|---|---|

| Four-Column Hydraulic Press | Max Pressure 120 Tons | Ensures consistent pallet density and durability |

| Automatic PLC Control System | User-Friendly Interface with Process Automation | Reduces manual errors, boosts throughput |

| Safety Protection Devices | Emergency Stop, Overload Protection | Minimizes workplace accidents, reduces downtime |

| Dual-Mode Operation | Pressing & Hot-Press Mode | Flexibility for different pallet types and wood materials |

Compared with conventional machines that often reach daily production outputs below 120 units, the dual-mode pressing wood pallet machine delivers a remarkable daily output of 240 pallets with consistent quality. This doubling in efficiency stems from automation, the advanced hydraulic system, and multi-mode pressing technology.

Operational costs reduce by nearly 30% due to energy-efficient hydraulics and minimized manual labor. Furthermore, enhanced safety protocols substantially reduce work injuries by an estimated 45%, translating to fewer production interruptions.

The adoption of this equipment empowers enterprises to scale production rapidly, meeting market demand without compromising product quality or environmental footprint. By transforming waste wood efficiently into durable pallets, clients contribute to a circular economy, reducing raw material wastage and carbon emissions.

GreenCycle Recyclers Ltd., a leading wood waste processing firm, integrated the dual-mode pressing wood pallet machine into their workflow six months ago. Their production supervisor shared:

“After switching to this machine, our daily pallet output skyrocketed from 110 to 240 units. The automated controls drastically reduced defects and labor costs while improving worker safety. Our clients have noticed the superior build quality, strengthening our brand reputation.”

GreenCycle also reported an approximate 25% reduction in energy consumption, underscoring the machine’s operational sustainability benefits.

Are you ready to revolutionize your wood pallet manufacturing and maximize production efficiency? Discover how Zhengzhou Tuoyu’s dual-mode pressing wood pallet machine can serve as the strategic asset your business needs.

Explore Dual-Mode Pressing Wood Pallet Machine Solutions →

We'd love to hear your thoughts! What are your biggest challenges in wood pallet production? Leave a comment below or contact our sales team for tailored advice.