In the competitive world of pallet manufacturing, every minute counts—and so does every dollar spent on production. According to industry benchmarks from the International Woodworking Federation (IWF), companies that upgraded to modern roller-type wood chippers saw an average 27% increase in throughput within six months. That’s not just incremental improvement—it’s transformational.

Unlike older horizontal or disc-style chipper models, today’s roller-type wood chippers offer superior consistency, reduced downtime, and lower labor costs. A case study from a mid-sized pallet manufacturer in Georgia showed they saved over 120 hours per month by switching to a high-torque roller system—equivalent to hiring one full-time operator less.

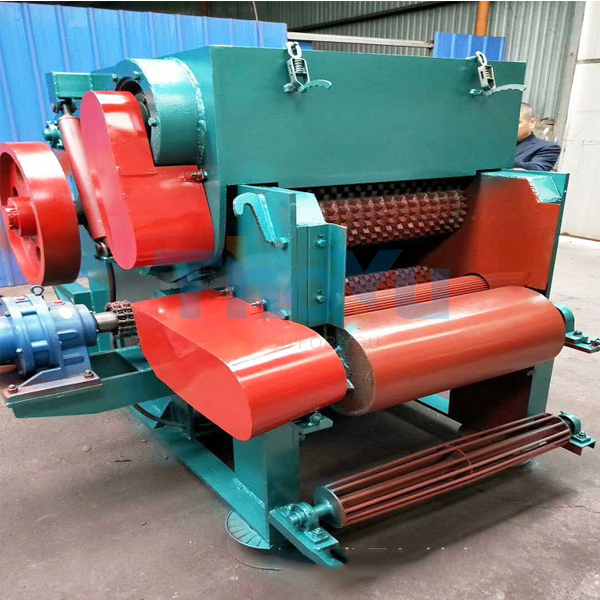

The key? Precision design. These machines feature dual counter-rotating rollers that gently feed logs while maintaining uniform chip size—a critical factor for consistent kiln drying and glue bonding in pallet assembly lines.

For manufacturers aiming to meet growing demand without expanding floor space or workforce, these machines are no longer optional—they’re essential.

With global ESG standards tightening, especially in EU and North America markets, sustainable practices like reducing wood waste and optimizing energy use are now part of compliance—not just best practice. A recent Wood Pulp & Pallet Association report found that 68% of buyers now prefer suppliers who can demonstrate clear environmental metrics in their production process.

That’s where the right chipper makes a difference—not only in output but in perception. When you can show your customers that each pallet is made with less raw material and more precision, you’re not just selling products—you’re building trust.

What’s your biggest challenge in managing wood processing efficiency today? Share your experience below—we’re listening.

Explore how our roller-type wood chipper can reduce waste, boost speed, and simplify maintenance—without breaking the bank.

See How It Works →