In the highly competitive pallet manufacturing industry, efficiency is the key to survival and success. Traditional wood chippers, however, often fall short in meeting the increasing demand for high - speed and cost - effective production. These traditional machines are plagued with issues such as low processing capacity, high maintenance requirements, and limited adaptability to different wood chip sizes. For example, they typically have a complex structure that makes maintenance time - consuming and costly, and they struggle to achieve consistent results in terms of wood chip quality.

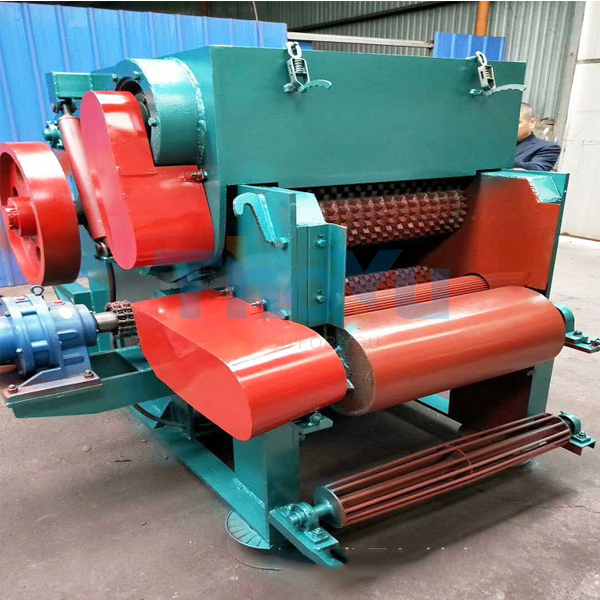

The drum wood chipper is designed with a simplified structure that brings significant maintenance convenience. Its core components include a sturdy frame, hammer blades, and an induction fan. The simplified design reduces the number of parts that need regular inspection and replacement. For instance, the frame provides a stable foundation for the entire machine, while the hammer blades are precisely engineered to efficiently chip the wood. The induction fan helps to transport the chipped wood out of the machine, ensuring a smooth operation. This straightforward design not only saves time during maintenance but also reduces the overall cost of ownership.

One of the standout features of the drum wood chipper is its customizable screen mesh. Different pallet manufacturing processes require different wood chip sizes. With the customizable screen mesh, the chipper can meet a wide range of particle size requirements. Whether you need fine wood chips for high - end pallets or larger chips for more general applications, the chipper can be easily adjusted to produce the desired results. This flexibility gives pallet manufacturing companies a competitive edge in the market.

The hydraulic buffer system is another crucial technology that ensures the smooth operation of the chipper. It effectively absorbs the shocks and vibrations generated during the chipping process, reducing wear and tear on the machine. This not only extends the lifespan of the chipper but also provides a more stable working environment, resulting in higher - quality wood chips.

When compared to traditional wood chippers, the drum wood chipper offers remarkable productivity advantages. It has a processing capacity of 5 - 20 tons per hour, which means that one drum wood chipper can replace three traditional machines. This significant increase in productivity leads to substantial savings in labor costs. For example, with the traditional machines, more workers are needed to operate and maintain the equipment, while the drum wood chipper requires fewer personnel, allowing companies to re - allocate their human resources to other value - added tasks.

The drum wood chipper also comes with several practical features that enhance its usability. The reverse feeding protection mechanism protects the machine from damage caused by incorrect feeding, ensuring a longer service life. The hydraulic opening of the crushing chamber cover makes it easy to access the internal components for maintenance and cleaning. These features are especially useful in high - volume production environments where time is of the essence.

It's important for pallet manufacturing companies to choose the right configuration of the drum wood chipper based on their production volume and raw material characteristics. Different production scenarios may require different screen mesh sizes and hydraulic buffer settings. By carefully considering these factors, companies can maximize the efficiency and performance of the chipper.

Are you interested in learning more about how our drum wood chipper can transform your pallet manufacturing process? Click here to further consult or request a trial. Your factory currently faces which chipping efficiency bottlenecks? Welcome to leave a message and discuss!