In today's highly competitive global market, pallet manufacturing enterprises are constantly seeking ways to reduce production costs and improve efficiency. The high - efficiency drum wood chipper has emerged as a game - changer for these businesses, offering significant benefits that align with the industry's trends.

Let's take a look at a real - world example. A medium - sized pallet manufacturing company was facing challenges in its wood processing stage. The traditional wood chipping equipment they used was slow, with a processing capacity of only about 5 cubic meters of wood per hour. This low - speed operation led to long production cycles and high labor costs. Moreover, the maintenance of the old equipment was frequent and costly, often resulting in production halts.

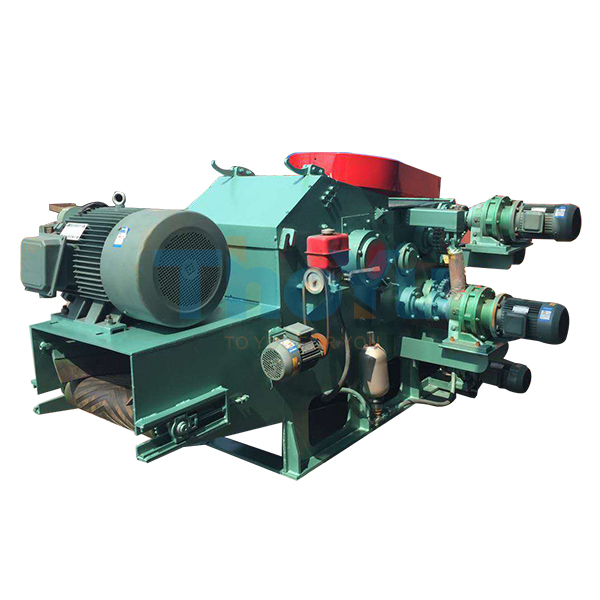

After evaluating various options, the company decided to invest in our high - efficiency drum wood chipper. This chipper is a specialized piece of equipment designed specifically for producing wood chips. Its simple design allows for easy replacement of parts, minimizing downtime during maintenance.

One of the most significant advantages of the drum wood chipper is its high processing speed. With a powerful motor and advanced cutting technology, it can process up to 15 cubic meters of wood per hour, which is three times the capacity of the old equipment. This increase in production speed directly translates into shorter production cycles and higher output. For instance, in a month, the company was able to produce 30% more pallets than before, which significantly increased their market competitiveness.

Cost reduction is another key benefit. The drum wood chipper has a lower energy consumption rate compared to traditional chippers. It can save up to 20% on electricity bills, which is a substantial long - term cost saving for the enterprise. Additionally, the simple design reduces the need for complex maintenance, saving on both labor and parts costs. The company found that their maintenance costs were reduced by 40% after switching to the drum wood chipper.

The drum wood chipper is also highly adaptable. It is suitable for a wide range of wood types, including hardwood and softwood. This flexibility makes it an ideal choice for not only pallet manufacturing enterprises but also other related industries such as particleboard factories and medium - and high - density fiberboard factories.

To illustrate the performance improvement, we can compare the old equipment and the drum wood chipper in a table:

| Parameters | Old Equipment | Drum Wood Chipper |

|---|---|---|

| Processing Capacity (cubic meters per hour) | 5 | 15 |

| Energy Consumption (per month) | High | 20% lower |

| Maintenance Cost (per year) | High | 40% lower |

As the industry continues to evolve towards higher efficiency and lower costs, the drum wood chipper is well - positioned to meet the needs of modern enterprises. It not only helps businesses reduce costs and increase efficiency but also enables them to stay ahead of the competition.

Are you looking to improve your wood processing efficiency and reduce costs? Don't miss out on the opportunity to transform your business with our high - efficiency drum wood chipper. Contact us today to learn more about how it can benefit your enterprise!

Image of the drum wood chipper: