As global demand for wooden products continues to grow, the need for efficient and reliable wood processing equipment has never been more critical. In the context of modern manufacturing, especially in the pallet production industry, the choice between traditional wood chippers and advanced drum-type wood chippers plays a crucial role in determining operational efficiency, cost-effectiveness, and long-term profitability.

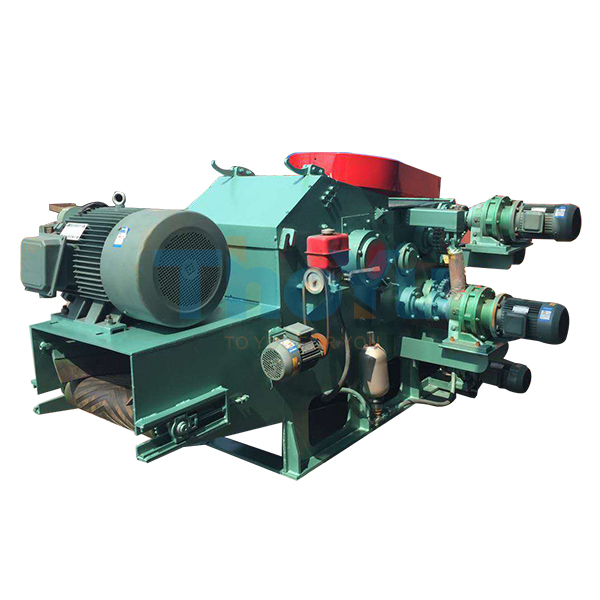

Drum-type wood chippers are designed with a rotating cylindrical chamber that houses cutting blades, allowing for continuous and uniform wood chip production. This design is particularly effective for handling large volumes of raw logs, ensuring consistent chip size and quality. Compared to traditional chippers, which often rely on fixed blades or discs, drum-type machines offer superior stability and durability under heavy-duty conditions.

To evaluate the performance differences, key parameters such as processing speed, chip quality, energy consumption, and maintenance frequency were analyzed across both types of machines. According to data from industry reports and field trials:

| Parameter | Traditional Wood Chipper | Drum-Type Wood Chipper |

|---|---|---|

| Processing Speed (kg/h) | 1,200 | 2,500 |

| Energy Consumption (kW/h) | 5.5 | 4.2 |

| Maintenance Frequency (hours) | Every 500 hours | Every 800 hours |

The data clearly demonstrates that drum-type wood chippers outperform their traditional counterparts in terms of productivity and energy efficiency, while also requiring less frequent maintenance, reducing downtime and overall operating costs.

In the pallet manufacturing sector, where high-volume and consistent output are essential, the advantages of drum-type wood chippers become even more pronounced. These machines are capable of producing uniformly sized chips, which are critical for maintaining the structural integrity of pallets. Additionally, the reduced energy consumption and lower maintenance requirements directly contribute to cost savings, making them an attractive investment for manufacturers aiming to optimize their operations.

A leading pallet manufacturer in Southeast Asia recently upgraded its wood processing system by replacing traditional chippers with drum-type models. The results were impressive: production capacity increased by 120%, energy costs dropped by 25%, and machine downtime was reduced by nearly 40%. This case highlights the tangible benefits of adopting advanced wood chipping technology.

With increasing pressure on manufacturers to reduce waste and improve sustainability, the demand for high-efficiency wood processing equipment is expected to rise. Drum-type wood chippers are well-positioned to meet these challenges, offering not only improved performance but also greater adaptability to evolving industry standards. As more companies recognize the long-term value of investing in advanced machinery, the market for drum-type wood chippers is projected to expand significantly over the next five years.

For businesses looking to stay competitive in the global wood processing market, upgrading to an efficient drum-type wood chipper is no longer just an option—it's a strategic necessity. Explore our range of high-performance wood chipping solutions today and take the first step toward a more productive and profitable future.

Discover Our Wood Chipper Solutions Now