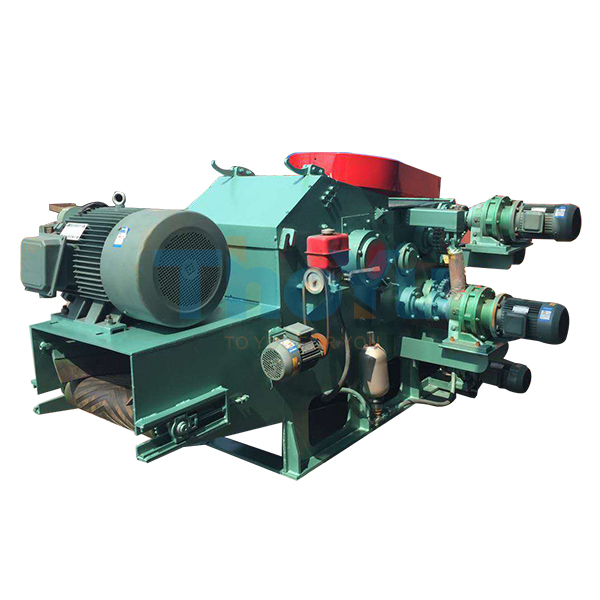

In today's competitive pallet manufacturing industry, improving operational efficiency and reducing labor costs are crucial challenges faced by production managers and procurement specialists worldwide. The high-efficiency drum wood chipper stands out as a breakthrough solution designed to meet these demands, providing a robust and reliable wood processing capacity ranging from 5 to 20 tons per hour with minimal downtime.

At the core of this drum chipper's success is its user-friendly structure that significantly reduces maintenance and changeover times. Featuring a hydraulic maintenance system and quick-change screens, operators can swiftly adjust the machine to process different wood species and sizes without complex disassembly. This flexibility is critical for pallet manufacturers who often juggle multiple wood qualities throughout production cycles.

The hydraulic buffering system ensures material feed stability, preventing wood jams and enhancing safety. This technology minimizes unexpected stoppages, maintaining a high throughput rate that surpasses many conventional shredding setups.

| Specification | Value / Capability |

|---|---|

| Processing Capacity | 5 to 20 tons/hour |

| Hydraulic Screen Change Time | Less than 15 minutes |

| Average Energy Consumption | 20% lower than comparable models |

| Downtime Reduction | 40% less maintenance stoppages annually |

The global wood processing sector increasingly emphasizes environmental responsibility alongside higher productivity. This drum wood chipper aligns perfectly with these trends by boosting resource utilization efficiency and reducing wood waste volume during pallet manufacturing. Its precision chipping results in consistent chip size, which optimizes subsequent pallet board drying and pressing processes, thus lowering energy consumption downstream.

Furthermore, the machine meets stringent emission and noise standards, ensuring a safer workplace and compliance with increasingly strict regulatory requirements across key export markets.

One leading pallet manufacturer in Eastern Europe recently adopted this drum wood chipper to replace three separate older chipping units. After installation, their production line experienced the following improvements:

These improvements translated directly into increased factory throughput and enabled the customer to scale production without expanding workforce size, proving the machine’s value as a strategic investment rather than just a line item expense.

“Integrating the high-efficiency drum wood chipper into our production not only slashed our processing times but also enhanced chip consistency, which improved downstream drying effectiveness by nearly 15%. The hydraulic system brings true ease of maintenance that reduced our downtime drastically.” — Operations Manager, Eastern European Pallet Producer

As pallet manufacturing demands continue to evolve, embracing machinery that delivers consistent output with operational ease is indispensable. This drum wood chipper facilitates a future-ready plant setup that balances high capacity with sustainable production practices.

Ready to elevate your production efficiency, reduce labor costs, and increase throughput with proven technology? Contact our sales team today for a personalized consultation and discover tailored solutions that fit your plant’s unique requirements.

We invite your questions or experiences with wood chipping solutions—please leave a comment below and join the conversation!