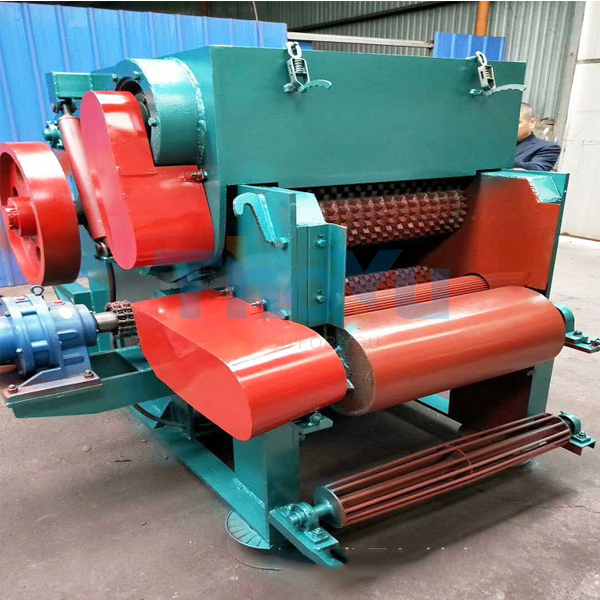

Pallet manufacturers worldwide are continually seeking innovative solutions to increase output without compromising quality or safety. Meeting this demand, the Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has developed an advanced pallet leg nailing machine tailored for European-style pallets and various block pallets. Combining automation, intuitive controls, and premium components, this machine transforms pallet production lines with remarkable efficiency gains.

This machine excels in functionality and user experience by integrating the following features:

As supply chains expand and green logistics grow in priority, pallet manufacturers face increasing pressure to optimize throughput and reduce waste. Traditional semi-manual nailing systems often result in frequent stoppages and inconsistent product quality, directly impacting cost-efficiency and customer satisfaction.

According to recent industry reports, automation adoption in pallet assembly has shown a 35-50% increase in daily output and a 20-30% reduction in operational downtime. The Pallet Leg Nailing Machine caters precisely to this need, offering a plug-and-play solution that minimizes learning curves and accelerates workflow continuity.

Operators benefit from the machine’s user-centric design, which significantly reduces the typical learning curve associated with complex equipment. Training programs focus on:

Real-world user feedback highlights the fast acquisition of skills—generally within 1-2 working days—enabling staff to quickly transition from training to full production, substantially reducing stop times and manual errors.

Companies leveraging the pallet leg nailing machine report:

These gains translate into enhanced market competitiveness and increased profitability, giving enterprises the agility needed to meet growing order volumes and quality standards.

“The implementation of automated nailing technology is no longer optional but essential to maintain operational excellence in pallet manufacturing.” – Industry Expert, PalletTech Insights 2024

What challenges have you encountered in your pallet production operations? How do you envision automation transforming your workflow? Share your insights and experiences below to foster a knowledge exchange among industry peers.