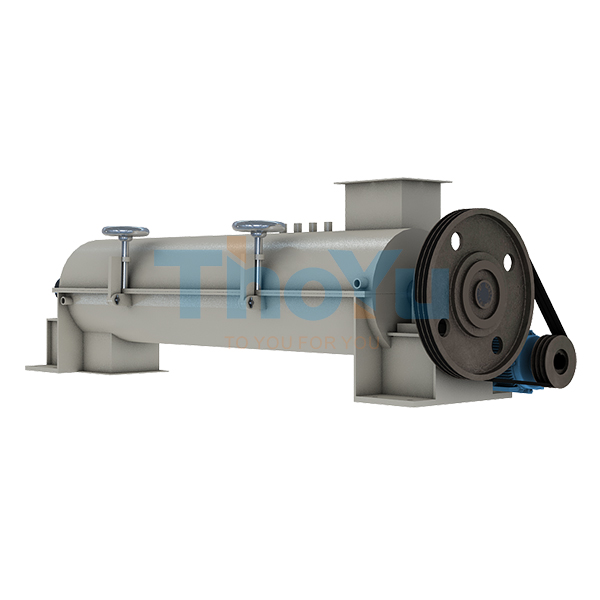

In today’s competitive pallet manufacturing industry, efficiency and precision are pivotal. Traditional pallet leg nailing equipment has long served the sector but often falls short in meeting modern production demands. Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has introduced its state-of-the-art pallet leg nailing machine that integrates advanced automation technologies with pinpoint nail positioning. This offers a transformative solution that successfully addresses the limitations of conventional devices.

Traditional nailing machines tend to rely heavily on manual intervention, resulting in inconsistent nail placements and slower cycle times. Frequent downtime for maintenance and adjustments further impact overall output. Additionally, the rigidity in operational parameters restricts customized adjustments based on varying pallet specifications, forcing manufacturers into a compromise between quality, speed, and flexibility.

The Tuoyu pallet leg nailing machine boasts a fully automated design powered by a robust PLC control system that regulates nailing sequences and ensures consistent operational precision. This automation slashes manual labor by up to 70%, as reported from multiple user case studies, while raising nailing speed by approximately 40% compared to traditional devices.

Precision is achieved through a state-of-the-art nail positioning mechanism that utilizes high-grade premium nail guns — carefully selected for their durability and consistency — paired with smart sensors. This combination guarantees each nail’s placement within a margin deviation of less than 0.5 millimeters, significantly reducing structural defects and enhancing finished pallet integrity.

Recognizing diverse manufacturing needs, the machine incorporates customizable nailing patterns and adaptable settings compatible with a wide range of pallet sizes and wood types. This flexibility eliminates the need for multiple machine models, streamlining factory floor operations and inventory.

Maintenance downtime is minimized thanks to modular components designed for rapid replacement and user-friendly diagnostics. Operators report an average reduction of 50% in unscheduled maintenance events, translating to increased machine availability and steady production flow.

One manufacturing customer implemented the Tuoyu machine and observed a 35% rise in daily production volume while simultaneously cutting labor costs by 25%. The automated machine reduced human error-related rework by nearly 80%, directly contributing to lower material waste and improved profit margins.

Comparatively, traditional devices often failed to sustain continuous production without multiple manual adjustments, frequently leading to unpredictable quality and costly downtime. The data strongly affirms the Tuoyu solution as an investment that leads to tangible operational enhancements.

How is your facility managing the challenges of pallet leg nailing? Have you explored automation solutions that balance precision with production speed effectively? Share your insights and experiences to foster industry-wide advancements in pallet manufacturing efficiency.