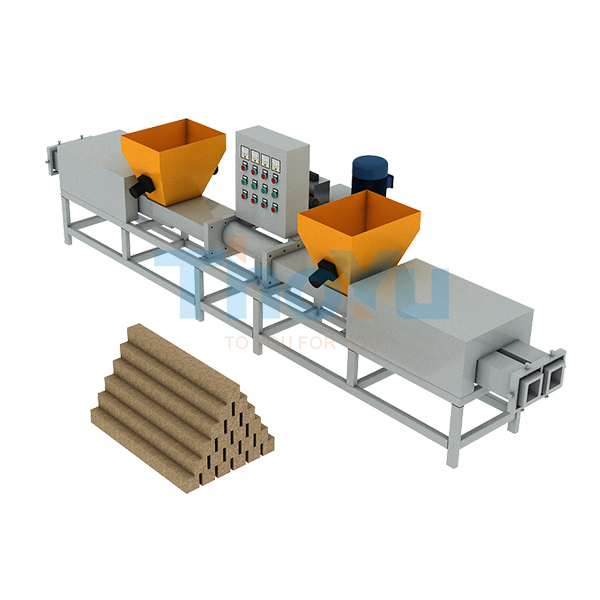

In the highly competitive world of pallet manufacturing, precision, efficiency, and operational cost-effectiveness define success. Traditional cutting saws, often limited by single-slice capacity and manual interventions, struggle to keep pace with the increasing demands. Enter Zhengzhou Tuoyu Electromechanical's automatic multi-blade cutting saw — a game-changer engineered specifically for pallet blocks under 100mm. This cutting-edge equipment enhances productivity, cuts down labor expenses significantly, and seamlessly adapts to different wood materials, setting a new benchmark for pallet producers globally.

Pallet factories traditionally face bottlenecks such as slow throughput, labor-intensive processes, and inconsistent cutting quality. Manual feeding and unloading, combined with limited cutting speed, inflate production costs and constrain scalability.

Zhengzhou Tuoyu’s fully automated cutting saw disrupts this status quo by integrating dual-blade synchronous cutting and an intelligent feed system that simultaneously slices two pallet blocks, enabling a staggering 30% reduction in labor costs. This innovation not only boosts cutting speed but also guarantees precise dimensions through smart automated size adjustments.

| Feature | Zhengzhou Tuoyu Cutting Saw | Market Mainstream Saws |

|---|---|---|

| Cutting Capacity | Up to 2 blocks (≤100 mm) simultaneously | 1 block per cycle |

| Labor Cost Reduction | 30% due to automation and feeding system | Minimal automation, high manual labor |

| Blade Quality | 60 & 80 teeth professional blades for smooth finish | Standard blades, frequent replacement required |

| Material Adaptability | Supports sawdust composites & solid wood | Limited to solid wood or sawdust only |

| Maintenance Cost | Lower due to modular design and quality components | Higher, frequent downtime and part replacements |

“Since integrating Tuoyu’s multi-blade cutting saw, we've seen a 40% increase in daily output with consistent block quality. The automated feeding system freed up our workers for other critical tasks, reducing overall labor expenses by 28%. It truly injects intelligent power into our production line.” — John Palmer, Operations Manager, UK-based Pallet Manufacturer

As Industry 4.0 accelerates, pallet factories must adopt intelligent manufacturing technologies to stay competitive. Zhengzhou Tuoyu cutting saw exemplifies this shift by combining CNC control with high-speed multi-blade cutting and automatic workflow integration. This translates to optimized raw material utilization – truly making every piece of wood count – and measurable boosts in production scalability.

Adopting such advanced cutting solutions positions pallet producers at the forefront of manufacturing innovation, empowering them to exceed market demands with agility and precision.