In today’s competitive manufacturing landscape, efficiency isn’t just a goal—it’s a survival strategy. For companies producing multi-layer plywood for packaging, construction, or furniture industries, the bottleneck often lies not in raw materials or design, but in how efficiently they handle pallet stacking and logistics preparation.

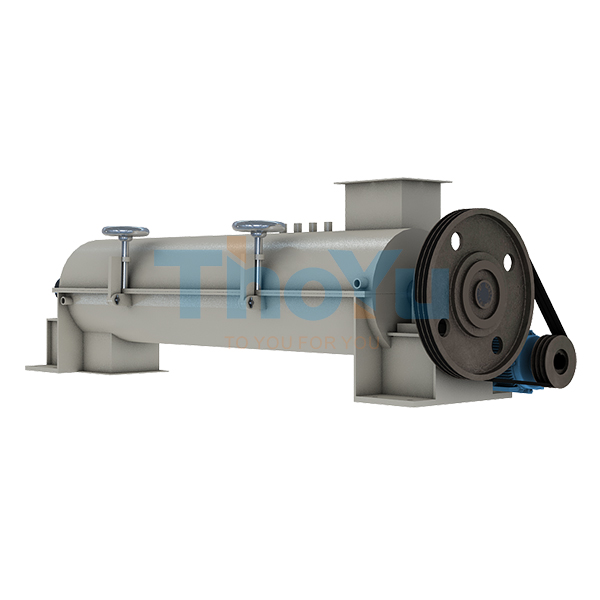

That’s where Zhengzhou Tuyu Machinery’s fully automated pallet stacker for multi-layer plywood comes in. This machine doesn’t just streamline operations—it transforms them. According to internal testing by Tuyu engineers, users report up to 40% faster production cycles compared to manual or semi-automated methods, while reducing labor costs by an average of 25–30% per shift.

The heart of this innovation is its intelligent operating system—designed with real-time feedback loops that adjust pressure, alignment, and speed based on board thickness and weight variations. In one case study from a European furniture manufacturer, the machine achieved a 99.2% consistency rate across 10,000+ units over three months—a level of repeatability previously unattainable manually.

Unlike many competitors relying on imported components, Tuyu uses domestically sourced high-grade actuators and sensors, ensuring long-term reliability even under heavy-duty conditions (up to 12 hours/day). This reduces downtime by up to 60%, according to client reports in Southeast Asia and the Middle East.

Whether you produce 500 or 5,000 panels per day, the system adapts. From adjustable frame widths (from 800mm to 1200mm) to modular stacking patterns tailored for different end markets—this isn’t a one-size-fits-all solution. One client in Dubai used it to optimize export-ready packaging for Gulf markets, reducing damage rates during transit by 35%.

And because every millimeter matters in high-value applications like premium flooring or industrial crates, the machine ensures zero deviation in stack height—even when switching between 3-ply and 12-ply configurations.

What makes this technology truly disruptive? It doesn’t just cut costs—it builds trust. Buyers in North America, Europe, and GCC countries increasingly demand digital traceability and quality assurance. With built-in data logging and remote diagnostics via cloud integration, your team can prove compliance with ISO standards effortlessly.

Ready to see how automation can transform your plywood workflow?

Explore Our Customized Automation Solutions Today

Get a Free Demo & Product Brochure