In the contemporary manufacturing landscape, the demand for efficient and high - quality production solutions is ever - increasing. The fully automatic multilayer plywood pallet block machine introduced by Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has emerged as a game - changer. This advanced equipment is designed to meet the global market's needs, with a focus on enhancing productivity and product quality.

Modern manufacturing requires speed and precision. According to industry research, traditional manual or semi - automatic methods for producing plywood pallet blocks have a production efficiency of only about 30 - 40 pieces per hour. In contrast, the fully automatic multilayer plywood pallet block machine can produce up to 100 - 120 pieces per hour, a significant improvement of 150% - 200%. This remarkable increase in production speed directly translates into higher output and faster order fulfillment, enabling manufacturers to keep up with market demands.

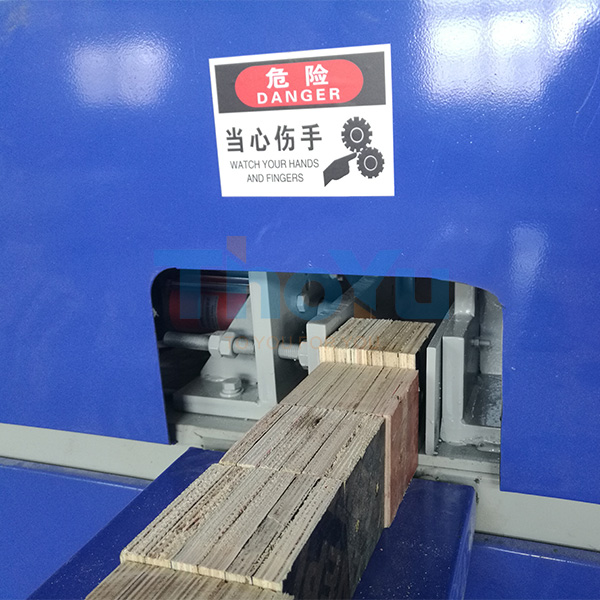

The automation technology integrated into this machine is the core factor that boosts both efficiency and product quality. The highly integrated intelligent system controls every step of the production process, from raw material feeding to the final product output. This ensures a high degree of precision and consistency in each pallet block.

For example, the automated cutting system can cut plywood with an accuracy of ±0.1mm, which significantly reduces material waste. On average, traditional methods may result in a material waste rate of 10% - 15%, while the automatic machine reduces this rate to less than 5%. This not only lowers production costs but also contributes to environmental sustainability.

Moreover, the intelligent quality control system continuously monitors the production process. It can detect any defects in real - time and automatically adjust the production parameters, ensuring that the final products meet the highest quality standards.

One of the most outstanding features of this machine is its strong customization ability. Different industries have different requirements for plywood pallet blocks in terms of size, shape, and load - bearing capacity. Zhengzhou Tuoyu's machine can be tailored to meet these specific needs.

For the logistics industry, which often requires large - sized and high - load - bearing pallet blocks, the machine can be adjusted to produce blocks with dimensions up to 1200mm×1000mm and a load - bearing capacity of over 2 tons. For the food and beverage industry, which has strict hygiene and safety requirements, the machine can be configured to use special materials and production processes to ensure compliance.

The reliability of the core components and the stability of the intelligent system are crucial for the long - term operation of the machine. Zhengzhou Tuoyu uses high - quality materials and advanced manufacturing processes for the core components of the machine, such as the hydraulic system and the transmission system.

The hydraulic system, for instance, is designed to withstand high pressures and has a service life of over 10,000 hours under normal operating conditions. The intelligent system is also highly stable, with a failure rate of less than 1% per year. This ensures that the machine can operate continuously for long periods without major breakdowns, minimizing production interruptions.

Many manufacturing enterprises have already benefited from using this machine. For example, a logistics company in Europe increased its pallet block production capacity by 200% after installing this machine. At the same time, the product quality improved significantly, leading to more business opportunities and a stronger market position.

So, are you ready to take your production to the next level with this state - of - the - art fully automatic multilayer plywood pallet block machine? Don't miss this opportunity to enhance efficiency, reduce损耗, and enjoy customized service. Click here to learn more and get in touch with us!