In today's highly competitive pallet manufacturing industry, improving production efficiency while minimizing equipment downtime is not just a goal—it’s a necessity. To address these challenges, Zhengzhou Tuoyu Electromechanical Equipment Co., Ltd. has introduced a cutting-edge pallet leg nailing machine that transforms traditional operations through innovation and user-centric design.

Pallet manufacturing typically involves repetitive nailing processes prone to frequent stoppages caused by mechanical failures or complex manual adjustments. Such downtime can lead to 10-15% productivity losses, directly impacting profitability. Additionally, long operator training cycles—often exceeding one week—further strain workforce resources and delay production ramp-up.

These hurdles underscore the urgent need for solutions that streamline machine operation, facilitate rapid workforce onboarding, and reduce unplanned stoppages.

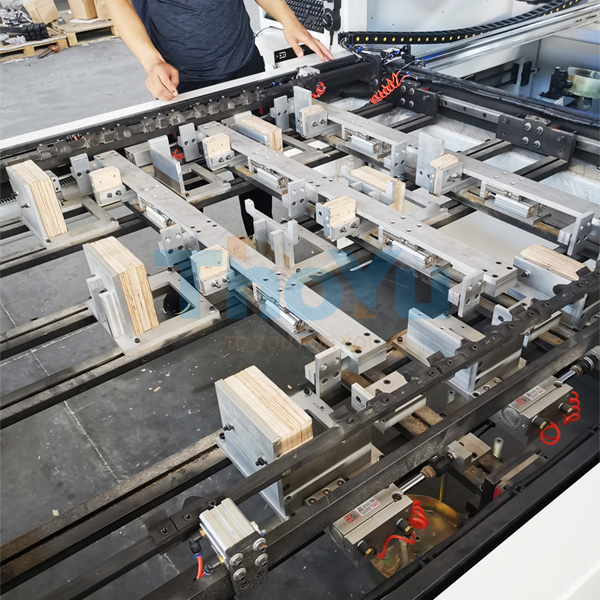

The pallet leg nailing machine by Zhengzhou Tuoyu integrates an advanced Programmable Logic Controller (PLC) system coupled with a user-friendly touchscreen panel. This combination enables highly precise nailing sequences adjustable via simple interface inputs, eliminating cumbersome manual calibration.

The PLC enhances process consistency and diagnostics, allowing predictive maintenance that minimizes unexpected downtime by up to 20%. Meanwhile, the touchscreen interface reduces the learning curve drastically, making it possible for operators to master equipment functionality within just three days.

Beyond automation intelligence, the device's streamlined mechanical design stands out for its ease of maintenance and adaptability. Operators can switch between manual and program-based modes seamlessly, catering to customized pallet specifications without interrupting downtime.

Modules utilize premium brand components, boosting reliability and reducing parts replacement rates by approximately 18%, ensuring long-term stable operations that support continuous production cycles.

The hallmark feature of this machine lies in its “three-day mastery” attribute. Simplified controls, alongside a structured training program supported by Tuoyu's technical team, enable rapid skill acquisition even among operators with minimal prior experience.

This results in shorter onboarding periods, significantly lowering training expenses and accelerating workforce deployment, crucial for manufacturers handling seasonal demand surges or labor turnover.

Equipped with this pallet leg nailing machine, manufacturers have consistently realized operational excellence marked by enhanced throughput and minimal downtime. The integration of automated precision, structural simplicity, and rapid training elevates production consistency and lowers operational risks.

Ultimately, this technology empowers pallet producers to meet growing market demands, strengthen client satisfaction, and secure a sustainable competitive advantage within the global supply chain landscape.